Ever turned the key, heard a slow crank, and wondered if the battery is really the problem? Those small warning signs often point to aging cells or the wrong battery type for the vehicle.

Specs tell the story before failure: voltage sag under load, CCA for cold starts, reserve capacity for accessories, and charge acceptance for start-stop use.

Reading these signals and matching them to vehicle type, climate, and driving patterns prevents breakdowns and overspending.

You’ll learn how to compare Flooded, AGM, EFB, Gel, and lithium-ion; read key ratings (Ah, CCA, RC, SOC/SOH); select the correct group size and terminal layout; and use a simple care routine with safe recycling.

The steps below show exactly how to choose with confidence and keep the electrical system steady.

Understanding Car Battery

A car battery is a rechargeable electrochemical energy storage system that supplies direct current (DC) to start the engine and power onboard electronics. It typically operates at 12 volts in conventional vehicles or 400–800 volts in electric vehicles.

The battery’s chemical reaction converts stored chemical energy into electrical energy, supporting critical functions when the alternator output is insufficient.

When you turn the key or press the start button, the battery delivers a quick burst of energy to ignite the engine. Beyond starting power, it also stores energy for when your car’s alternator isn’t generating enough electricity.

Over the years, car batteries have evolved from simple lead-acid units to more advanced types, including AGM, EFB, and lithium-ion.

Modern vehicles, especially those with start-stop systems or hybrid and electric drivetrains, rely on more efficient batteries designed to handle frequent charging cycles and higher energy demands.

Choosing the right battery isn’t just about compatibility; it ensures reliable performance, longer lifespan, and improved fuel efficiency for your car’s specific needs.

Main Types of Car Batteries

There are different types of car batteries, each designed to store power differently, handle temperature variations, and meet specific vehicle demands.

1. Flooded Lead-Acid (Wet Cell)

The most common and affordable automotive battery is known for its reliable performance and simple design.

How It Works: The flooded lead-acid battery is the most common and affordable type used in vehicles. It produces around 12.6 volts from six cells, each generating 2.1 volts, and offers 30–40 Wh/kg of specific energy.

The internal resistance ranges between 0.015–0.025 Ω, and it supports about 500–800 charge–discharge cycles at 50% depth of discharge (DOD). Its charge rate stays below 0.2C, and its lifespan typically falls between 3–5 years.

It’s vented, meaning it loses water through electrolysis and needs topping up every few months. These batteries usually weigh 18–22 kg, cost $50–$120, and deliver around 600 cold-cranking amps (CCA) for dependable starts.

Pros/Cons

| Pros | Cons |

|---|---|

| Provides up to 600 CCA for reliable ignition | Needs electrolyte refilling every 3–6 months |

| Easy to maintain and widely available | Heavy (≈18–22 kg) |

| Low upfront cost and recyclable | Loses 15% capacity yearly under high heat |

| Performs reliably in standard driving | Sensitive to vibration and deep discharge |

| 75–80% efficiency | — |

Best For: Basic cars, agricultural vehicles, or backup systems needing an affordable 12V power source for low to moderate current loads.

2. Absorbent Glass Mat (AGM)

A sealed, maintenance-free VRLA battery designed for modern cars with high electrical loads and start-stop systems.

How It Works: AGM batteries are sealed and maintenance-free, designed for vehicles with high electrical loads or start-stop systems. They use fiberglass mats to hold the electrolyte and prevent leakage.

Each unit produces 35–50 Wh/kg, charges up to 2C (reaching 80% in 30 minutes), and operates efficiently between -40°C and +60°C.

The internal resistance stays between 0.002–0.005 Ω, allowing quick charging and stable voltage. They typically last 4–7 years or about 1,000–1,200 cycles at 80% DOD, and cost $100–$250.

Pros/Cons

| Pros | Cons |

|---|---|

| Fast recharge (80% in 30 min) | Higher initial cost |

| Up to 900A CCA for strong cold starts | Sensitive to overvoltage (>14.8V) |

| Supports 50,000+ start-stop cycles | Requires smart alternator compatibility |

| Operates efficiently from -40°C to +60°C | Slightly heavier (20–25 kg) |

| Twice the lifespan of flooded batteries | More complex recycling process |

Best For: Modern cars with advanced electronics, high-current accessories, and start-stop systems demanding rapid recharge and stable output.

3. Enhanced Flooded Battery (EFB)

An improved lead-acid variant for fuel-efficient and start-stop vehicles needing faster recovery and moderate deep-cycle capability.

How It Works: EFBs are improved lead-acid batteries built for start-stop and fuel-efficient vehicles. They use reinforced grids and carbon additives for faster charge acceptance and longer life.

They deliver 35–45 Wh/kg of specific energy, with internal resistance of 0.006–0.010 Ω, and a charge rate up to 1.5C. These batteries can last 4–6 years or about 1,000 cycles at 50% DOD, and cost $120–$200.

EFBs recharge up to 70% faster than standard types and maintain stable voltage under frequent restarts.

Pros/Cons

| Pros | Cons |

|---|---|

| Handles 40,000+ start-stop cycles | Slightly heavier than AGM |

| 70% faster recharge rate | Limited deep discharge capability (>50% shortens life) |

| Maintains ≥12.4V during restart loads | Moderate performance below -25°C |

| Longer life than regular lead-acid | Needs precise voltage control |

| Performs well between -20°C and +55°C | Lower CCA (~700A) than AGM |

Best For: Fuel-efficient and city-driving vehicles with frequent start-stop operation and moderate accessory usage.

4. Gel Cell Battery

A vibration-resistant sealed lead-acid battery built for deep cycling and extreme climates.

How It Works: Gel batteries are sealed, vibration-resistant, and ideal for deep cycling in extreme conditions. They use a silica-thickened electrolyte, preventing leaks and allowing uniform ion flow.

Each unit produces 35–45 Wh/kg, operates between -30°C and +60°C, and lasts 5–7 years with 700–800 cycles at 50% DOD. Internal resistance ranges from 0.004–0.008 Ω, and the charging rate is limited to 0.3C. Costs range between $120–$250.

Pros/Cons

| Pros | Cons |

|---|---|

| Fully sealed, leak-proof design | Long recharge time (4–6 hours at 0.2C) |

| Reliable in -30°C to +60°C range | Sensitive to overvoltage (>14.4V) |

| Handles deep discharge to 80% DOD | Limited availability and higher cost |

| Low self-discharge and vibration-proof | Not ideal for short city drives |

| Maintenance-free operation | Slower high-current output |

Best For: Off-road vehicles, RVs, marine, and solar systems needing long runtime, deep-cycle stability, and rugged performance.

5. Lithium-Ion Battery

The most advanced battery type, known for high energy density, long life, and fast charging.

How It Works: Lithium-ion batteries are advanced, lightweight, and efficient. They use lithium-ion migration between graphite and metal oxide electrodes, producing 3.6–3.7V per cell and up to 350V in EV packs.

They deliver 120–265 Wh/kg of energy, charge to 80% in 30 minutes at 2C, and maintain more than 80% capacity after 2,000–3,000 cycles.

Internal resistance remains low (0.001–0.003 Ω), with a lifespan of 8–10 years. Costs range from $200–$800+, depending on chemistry.

Pros/Cons

| Pros | Cons |

|---|---|

| 90%+ efficiency and fast charging | Expensive to produce and replace |

| Lightweight (6–8 kg for 12V pack) | Requires Battery Management System (BMS) |

| 3× the lifespan of AGM batteries | Degrades faster above 45°C |

| Supports high discharge without voltage drop | Sensitive to overvoltage (>4.2V per cell) |

| Operates from -20°C to +60°C | Limited recyclability for some chemistries |

Best For: Hybrid and electric vehicles requiring high power density, 2,000+ cycles, and rapid recharging for daily or long-distance operation.

6. Silver-Calcium Battery

A high-durability lead-acid battery that uses silver-calcium alloy grids to improve lifespan, corrosion resistance, and heat stability.

How It Works: Silver-Calcium batteries are durable lead-acid variants using silver-alloy grids for heat resistance and longer service life. They produce 12.6V nominal, deliver 40–50 Wh/kg, and operate with 0.010–0.015 Ω internal resistance.

Their lifespan averages 5–7 years or about 900 cycles at 50% DOD. Charging should stay below 0.5 °C, and they typically cost $150–$250. These batteries handle high heat with minimal water loss, making them ideal for demanding vehicles.

Pros/Cons

| Pros | Cons |

|---|---|

| Extended life in hot climates | Needs higher charging voltage (>14.4V) |

| Corrosion-resistant alloy | Not compatible with older alternators |

| Low water loss and stable output | Slightly higher cost than standard lead-acid |

| Resists sulfation and high heat | Weaker deep-discharge capability |

| Lower self-discharge rate | Less effective in very cold regions |

Best For: Vehicles in hot environments or those with high electrical demand, such as luxury sedans and performance cars.

7. VRLA (Valve-Regulated Lead-Acid) Battery

A sealed, maintenance-free battery that prevents electrolyte leakage and allows internal gas recombination for longer, cleaner operation.

How It Works: VRLA batteries are sealed, maintenance-free systems that prevent leaks and allow internal gas recombination. They use pressure-regulated valves and either AGM or gel electrolytes.

Producing 35–45 Wh/kg, they last 5–8 years with about 1,000 cycles at 50% DOD. Internal resistance ranges from 0.004–0.010 Ω, with a charge rate of 0.3C. They cost around $120–$300 and are safe for use in enclosed setups.

Pros/Cons

| Pros | Cons |

|---|---|

| Sealed, leak-proof design | Sensitive to overcharging (valve damage) |

| No maintenance or water refilling | Slower recharge time than AGM |

| Works in any orientation | Lower cold-cranking power |

| Long service life and clean operation | Higher cost than flooded batteries |

| Minimal self-discharge | Hard to repair if sealed fails |

Best For: Enclosed systems, backup power units, or vehicles where safety and zero maintenance are priorities.

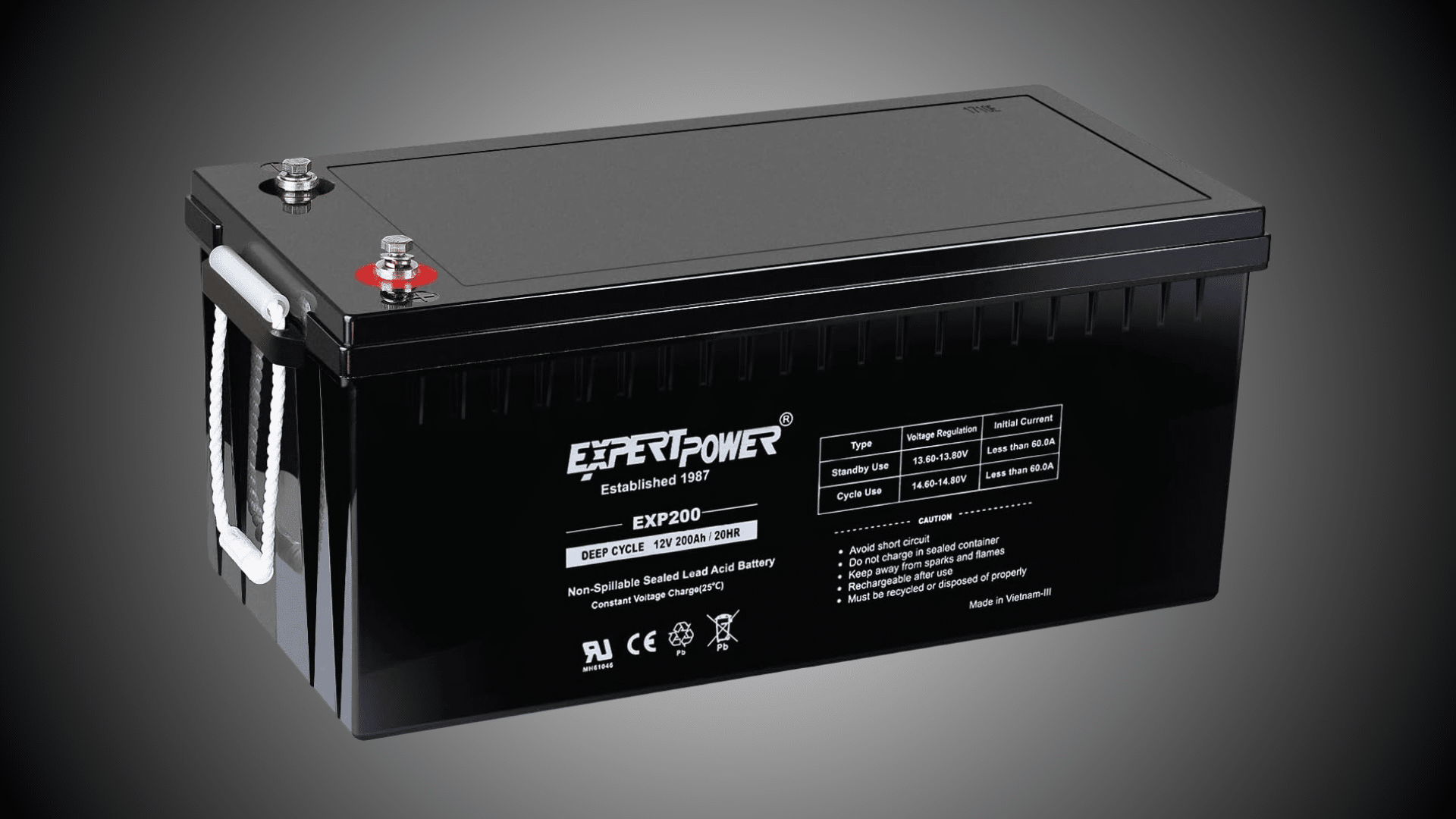

8. Deep-Cycle Battery

A heavy-duty lead-acid design built to provide steady, continuous power over long discharge periods rather than short bursts.

How It Works: Deep-cycle batteries are built for steady, long-duration energy output. They use thick lead plates to tolerate deep discharges up to 80% DOD and can last 5–8 years or 1,200 cycles.

Each unit provides 12V nominal, 40–60 Wh/kg energy, 0.005–0.010 Ω resistance, and a ≤0.5C charge rate. They cost $150–$300 and work well in solar and marine setups needing continuous power.

Pros/ Cons

| Pros | Cons |

|---|---|

| Handles 80% deep discharges | Heavier than standard batteries |

| Long cycle life for renewable setups | Slower to recharge |

| Consistent voltage under sustained loads | Not ideal for short trips |

| Durable and vibration-resistant | Requires a specific charger |

| Reliable for off-grid systems | More expensive than basic types |

Best For: Solar systems, RVs, boats, and industrial setups requiring a stable, long-duration energy supply.

Car Battery Comparison Table

This quick chart compares major car battery types by lifespan, maintenance needs, cost, and best use, helping you choose confidently.

| Battery Type | Voltage (V) | Specific Energy (Wh/kg) | Cycle Life | Optimal Temp (°C) | Typical Use |

|---|---|---|---|---|---|

| Flooded Lead-Acid | 12.6 | 30–40 | 500–800 | 25 | Basic vehicles |

| AGM | 12.6 | 35–50 | 800–1,000 | -20 to 60 | Start-stop vehicles |

| EFB | 12.6 | 40–55 | 1,000+ | -20 to 55 | Fuel-efficient cars |

| Gel | 12.6 | 35–45 | 700–900 | -40 to 70 | Off-road |

| Li-Ion | 350–800 (EVs) | 120–260 | 1,500–3,000 | -20 to 60 | Hybrids/EVs |

How to Choose the Right Car Battery

Selecting the right car battery helps your vehicle start easily, last longer, and perform well under different driving habits and weather conditions.

Step 1: Match the Battery to Your Vehicle Type

Different vehicles draw varying current loads and require specific discharge profiles.

- Compact cars: Work efficiently with 45–60 Ah flooded or EFB batteries providing ~500 CCA.

- SUVs and trucks: Require 70–90 Ah AGM batteries with ≥700 CCA to handle power-hungry systems like heaters, defrosters, and infotainment.

- EVs and hybrids: Use high-voltage lithium-ion modules (200–400 V packs) with integrated battery management systems (BMS) that maintain cell balance and thermal stability.

Always confirm voltage (12 V, 24 V, or hybrid HV range) and group size in the owner’s manual to prevent electrical mismatches.

Step 2: Check Compatibility and Specifications

Match your vehicle’s nominal voltage, amp-hour (Ah) rating, and cold-cranking amps (CCA) to manufacturer standards.

- A battery rated below the required Ah or CCA can lead to slow cranking and alternator overload.

- Over-sized batteries may undercharge, causing sulfation or cell stratification.

Typical passenger cars need 12 V batteries rated 45–80 Ah with CCA between 500–800 A, depending on engine displacement.

Always ensure terminal polarity and tray dimensions match OEM specs to avoid wiring strain and poor contact resistance.

Step 3: Consider Your Driving Habits

Driving patterns directly affect cycle life and charge acceptance.

- Frequent short trips: Prevent full recharge, leading to sulfation. Use AGM or EFB batteries with high charge acceptance (>1.5 A/Ah) to handle partial-state-of-charge conditions.

- Long highway drives: Allow full recharge; flooded lead-acid batteries perform well when regularly cycled to 100% SOC.

Vehicles with start-stop systems demand units rated for 50,000+ engine restarts and high DCA (Dynamic Charge Acceptance) to maintain voltage stability during idling periods.

Step 4: Evaluate Climate and Temperature

Temperature extremes influence chemical kinetics and internal resistance.

- Cold climates (≤–20 °C): Choose batteries with ≥600 CCA to maintain cranking power.

- Hot regions (≥50 °C): Opt for heat-resistant AGM or Gel Cell designs rated for continuous operation up to 60 °C.

Proper venting prevents electrolyte evaporation and plate corrosion.

Always verify the manufacturer’s operating temperature range and CCA-to-weight ratio, as excessive heat shortens battery life by accelerating grid oxidation.

Step 5: Compare Cost and Lifespan

Evaluate based on cost per cycle and usable energy output.

- Flooded lead-acid: 500 cycles @ 80% DOD → ~$0.20 per cycle.

- EFB: 700 cycles @ 80% DOD → ~$0.17 per cycle.

- AGM: 900 cycles @ 80% DOD → ~$0.15 per cycle.

- Lithium-ion: 2,000+ cycles @ 80% DOD → ~$0.10 per cycle.

Quantifying value this way reveals long-term cost efficiency beyond initial price.

Step 6: Check Brand, Warranty, and Reliability

Look for brands that publish IEC 60095 or SAE J537 test certifications. Warranties of 36–60 months reflect real-world durability.

Choose batteries with cycle-life ratings, CCA tests, and temperature-compensated charge algorithms validated under these standards.

Premium brands also provide embedded QR or RFID tracking for traceability of manufacturing date and lot performance.

Use This Quick Checklist Before Buying:

Before making your final choice, make sure you’ve covered all the essentials:

- Check your vehicle manual for size, voltage, and specs.

- Identify if your car uses start-stop or hybrid technology.

- Match battery life span with your budget.

- Verify correct terminal position and polarity.

- Consider local climate and driving patterns.

- Review brand reputation and warranty period.

Choosing with care ensures your battery lasts longer, performs better, and keeps your vehicle running smoothly in every condition.

New and Emerging Battery Technologies

Modern research is creating next-generation batteries that are safer, last longer, and use more sustainable materials for cars and electric vehicles.

Sodium-Ion Batteries

Sodium-ion cells replace lithium (Li⁺) with sodium (Na⁺) ions, moving through a non-flammable electrolyte of carbonate solvents and sodium salts.

They typically use hard-carbon anodes and Prussian-blue analog (PBA) cathodes, both inexpensive and stable materials.

While their specific energy (≈ 100 – 160 Wh/kg) is lower than lithium-ion (≈ 200 – 260 Wh/kg), sodium-ion batteries excel in cold-temperature performance, retaining > 80 % capacity at –20 °C.

The chemistry’s reliance on abundant sodium makes it highly scalable and cost-efficient for grid storage and affordable electric vehicles.

Solid-State Batteries

Solid-state batteries replace liquid electrolytes with ceramic or polymer-based solid conductors, such as lithium lanthanum zirconate (LLZO) or sulfide-based materials.

This solid matrix allows ionic conductivity up to 10⁻³ S/cm, while eliminating the risk of dendrite formation — a primary cause of short circuits in conventional Li-ion cells.

Prototype systems have achieved 400 – 500 Wh/kg energy density, roughly double today’s lithium-ion packs, with charging times under 10 minutes.

These characteristics could extend electric-vehicle range to > 1,000 km per charge while improving thermal safety and cycle life beyond 1,500 cycles at 80 % DOD.

Cobalt-Free and Metal-Air Batteries

Cobalt-free chemistries (e.g., lithium iron phosphate – LiFePO₄ or nickel-manganese-oxide – NMO) eliminate reliance on expensive, ethically sensitive metals.

Metal-air systems, including zinc-air (Zn–O₂) and aluminum-air (Al–O₂), use atmospheric oxygen as the cathode reactant, achieving theoretical energy densities above 800 Wh/kg.

Although still in prototype stages, these batteries promise lightweight construction, lower costs, and enhanced recyclability once oxygen diffusion and electrolyte-stability challenges are resolved.

The Future of Car Batteries

Car batteries are evolving rapidly with better materials, safer designs, and global manufacturing growth, shaping the next generation of vehicles.

Ongoing Lithium-Ion Advancements

Lithium-ion batteries will continue to lead the market in the near future. Ongoing research focuses on improving energy density, enabling faster charging, and extending lifespan.

Manufacturers are reducing weight and improving thermal stability to make batteries safer and more efficient. Recycling systems are also expanding to recover valuable metals.

These improvements will keep lithium-ion technology relevant and practical for electric and hybrid vehicles until newer solutions become more affordable and widely available.

Rise of Solid-State and Sodium-Ion Cells

Solid-state and sodium-ion technologies are gaining strong momentum. They promise higher safety, faster charging, and improved performance in extreme temperatures.

Solid-state batteries use solid electrolytes, reducing leakage and fire risk, while sodium-ion batteries offer low-cost, abundant material use.

Toyota announced breakthroughs in solid-state battery durability and plans for mass production by 2027–2028.

The company expects these batteries to offer up to 1,000 km (621 miles) of range and 10-minute fast charging. Alongside this, Toyota is developing improved lithium-ion and cobalt-free options to lower costs and extend vehicle range.

Industry Trends and Expansion

The battery industry is entering a period of major growth and diversification.

- Purpose-built batteries: Designed for specific vehicles such as EVs, hybrids, and trucks.

- Manufacturing growth: New large-scale plants in the US, China, and Europe.

- Geographic diversification: Expanding production beyond Asia to stabilize supply chains.

- Cost reduction: Prices are expected to drop by nearly 50% by 2026, making electric vehicles more affordable for everyday drivers.

Emerging Concepts to Watch

New research is exploring materials and designs that may redefine battery performance.

- Metal-air batteries: Lightweight zinc-air and aluminum-air models promise high energy density.

- Graphene-enhanced cells: Improve conductivity, reduce charging time, and boost lifespan.

- Recyclable and modular packs: Allow easier replacement, recycling, and reuse of battery components.

These developments could make future batteries cleaner, cheaper, and more adaptable to diverse vehicle types and global sustainability goals.

Car Battery Recycling and Environmental Responsibility

Proper recycling and cleaner manufacturing help reduce pollution, recover valuable materials, and make modern car batteries safer for the planet.

Safe Disposal Practices

Car batteries contain materials that can harm soil and water if not handled correctly. Always return old batteries to certified recycling centers or auto shops that follow approved disposal methods.

Avoid throwing them in household waste. Many retailers and service stations accept used batteries for safe transport to recycling facilities, where they’re processed under strict environmental standards to prevent leakage and toxic contamination.

Material Recovery and Recycling

Modern recycling processes recover:

- 99 % of lead from lead-acid batteries

- 95 % of nickel from NiMH and lithium-ion cells

- 70 % of lithium is used in hydrometallurgical and direct-recovery methods

A closed-loop system saves up to 60 % CO₂ emissions compared with raw-material extraction and reduces total energy use by 40 – 50 %.

Recovered metals are refined and reused in new cathodes, cutting dependence on mining while maintaining consistent electrochemical quality.

Eco-Friendly Industry Shifts

New gigafactories are powered by solar and wind energy, reducing lifecycle emissions by 25 – 35 % per kWh produced.

Low-emission cathode production uses aqueous binders instead of volatile N-methyl-2-pyrrolidone (NMP), cutting harmful solvent output by 90 %.

Manufacturers are also introducing closed-loop water systems and AI-based thermal-management controls, further lowering waste heat and chemical discharge.

These data-backed innovations demonstrate measurable progress toward carbon-neutral battery production.

Final Thoughts

Now you know how to choose the right car battery and which specs matter most. Your decision hinges on vehicle type, climate, driving pattern, and basic upkeep, not just price.

Most daily drivers are well served by EFB or AGM, while hybrids and EVs depend on lithium-ion. Smart charging, correct CCA and Ah sizing, and routine checks extend service life and cut total cost per cycle.

Track cold starts, accessory load, resting voltage, and battery age. Match chemistry to your conditions and you’ll avoid no-start surprises while keeping the electrical system steady.

I encourage you to verify fitment and specs at a trusted shop. Drop a comment below with the battery type you’re considering or any sizing questions you want answered.