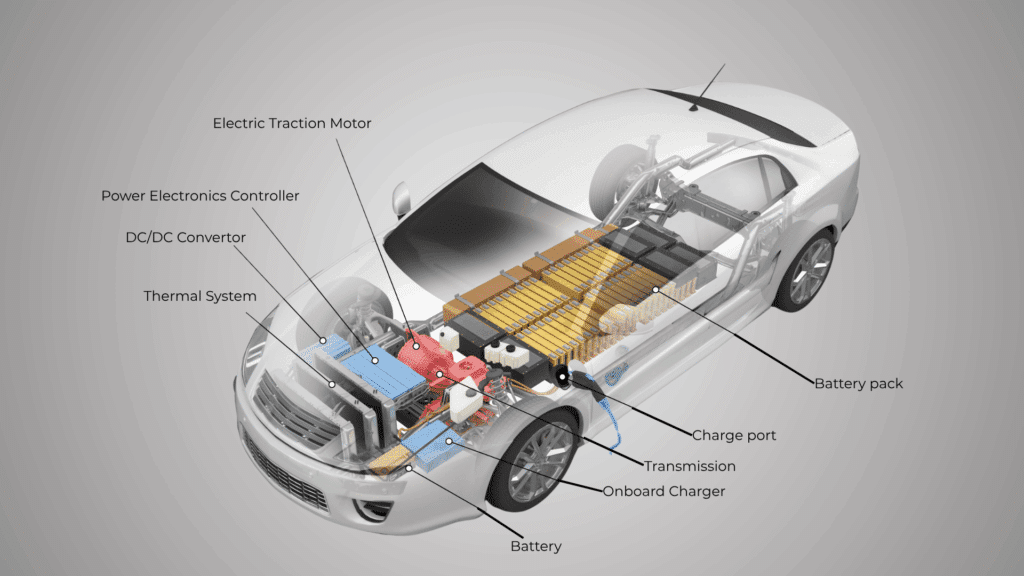

Have you ever thought about what makes electric vehicles so different from traditional cars under the hood? Electric vehicles operate on completely different principles with unique parts that work together to provide smooth transportation.

Electric vehicle components help you appreciate the engineering behind these increasingly popular cars on our roads.

Unlike conventional vehicles with hundreds of moving engine parts, EVs use simpler systems centered around batteries and motors.

Each component plays a specific role in converting stored electrical energy into motion that propels the vehicle forward.

How an Electric Vehicle Functions

Electric vehicles operate by drawing power from a large battery pack that stores electrical energy for propulsion.

When you press the accelerator, the battery sends electricity to the electric motor through Smooth power electronics. The motor converts this electrical energy into mechanical rotation that turns the wheels and moves the car forward.

Electric vehicle components work together in a coordinated system managed by onboard computers that constantly optimize performance.

The battery recharges through regenerative braking that captures energy during deceleration and through plugging into charging stations.

An efficient system requires fewer moving parts and less maintenance compared to traditional combustion engines.

Most Important Part of an Electric Car

Electric vehicles rely on several critical components that work together, each serving essential functions for performance, efficiency, and reliable operation.

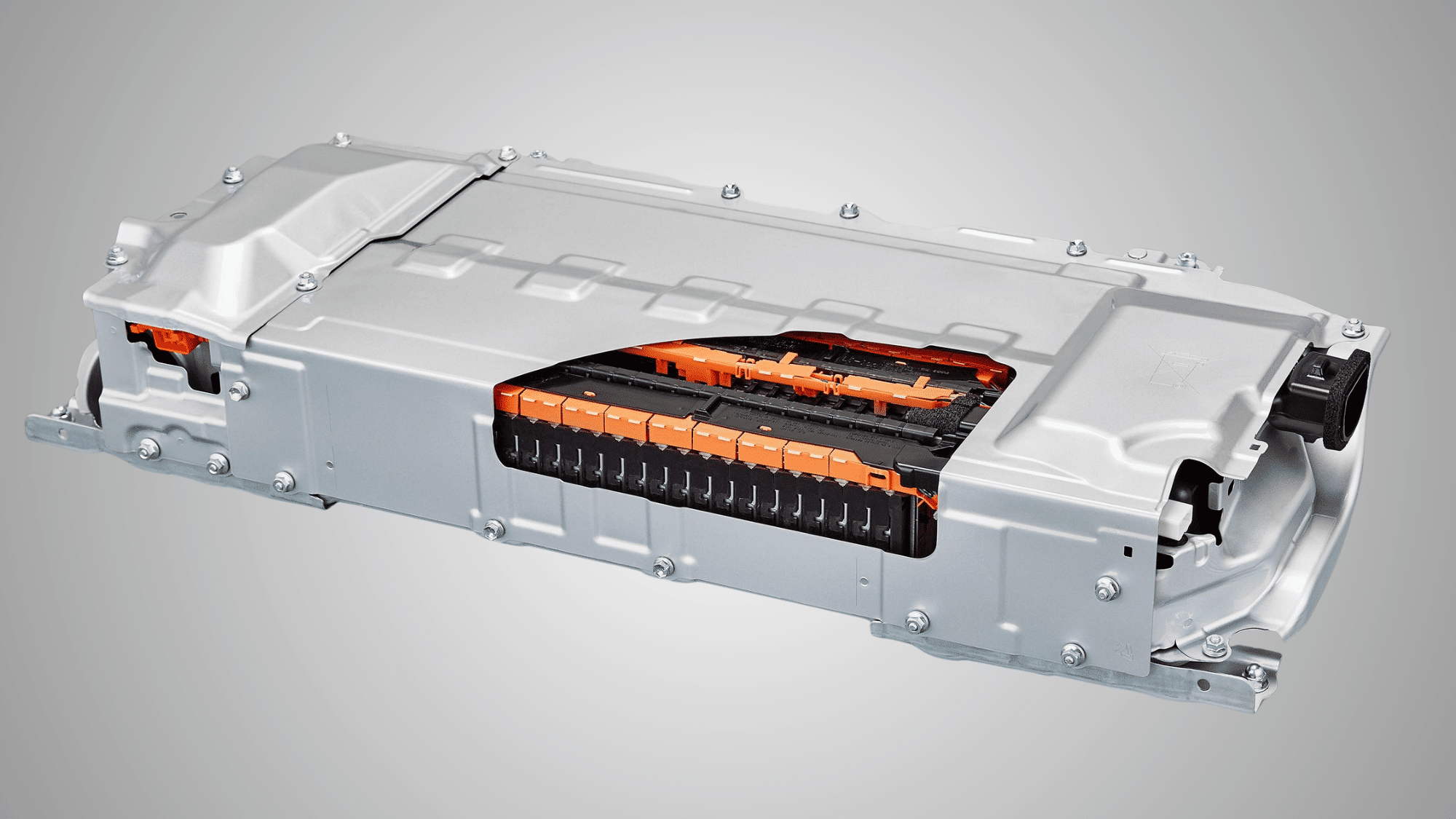

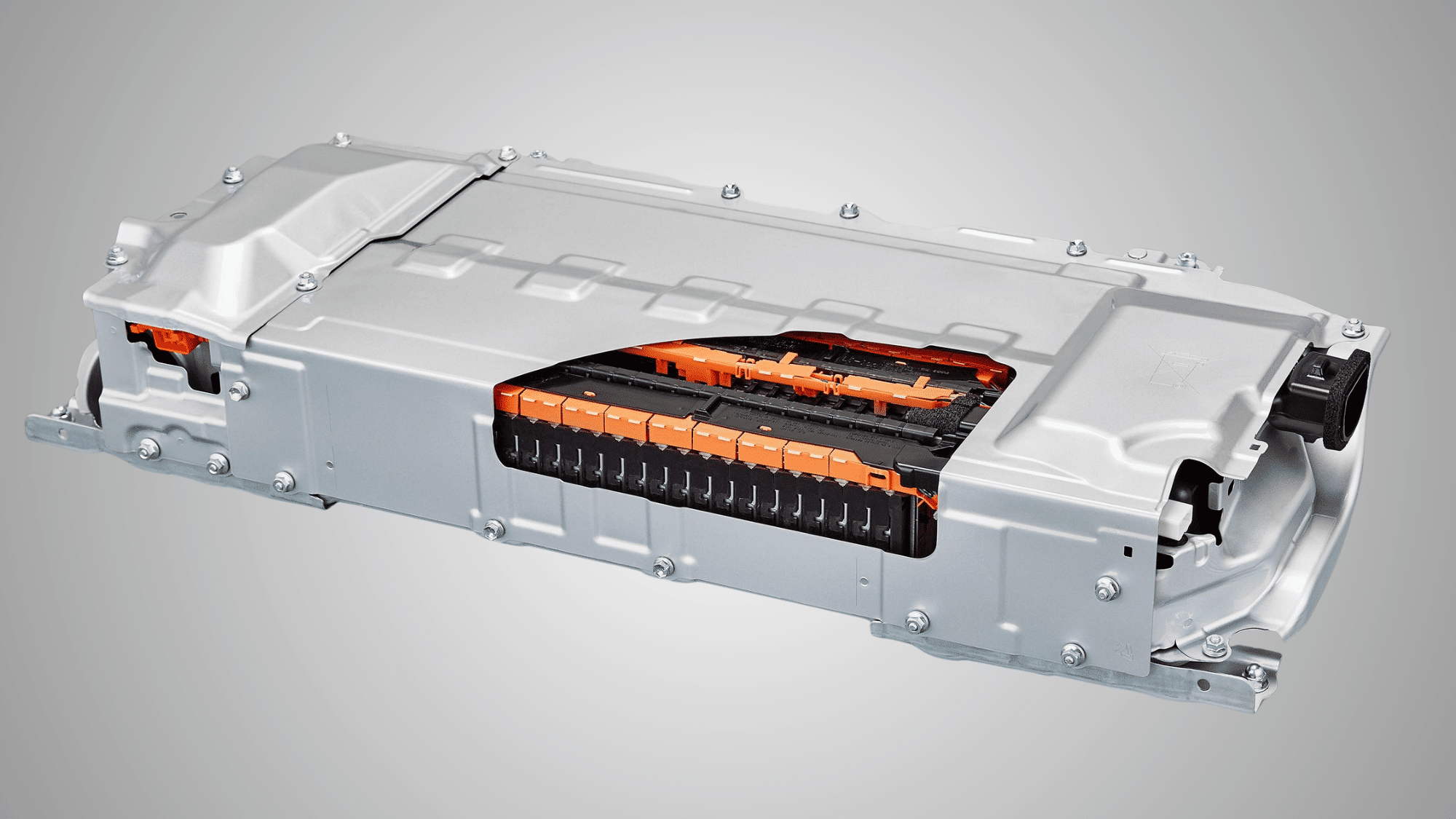

1. Battery Pack

The battery pack functions as the primary energy reservoir, storing electrical power that propels the vehicle and operates all auxiliary systems, from climate control to infotainment.

Constructed from thousands of lithium-ion cells arranged in protective modules distributed throughout the chassis floor, this component determines overall vehicle capability.

Battery capacity measured in kilowatt-hours directly correlates to the distance traveled per charge.

Modern packs maintain 70-80% original capacity after 8-10 years of regular use under manufacturer warranty coverage.

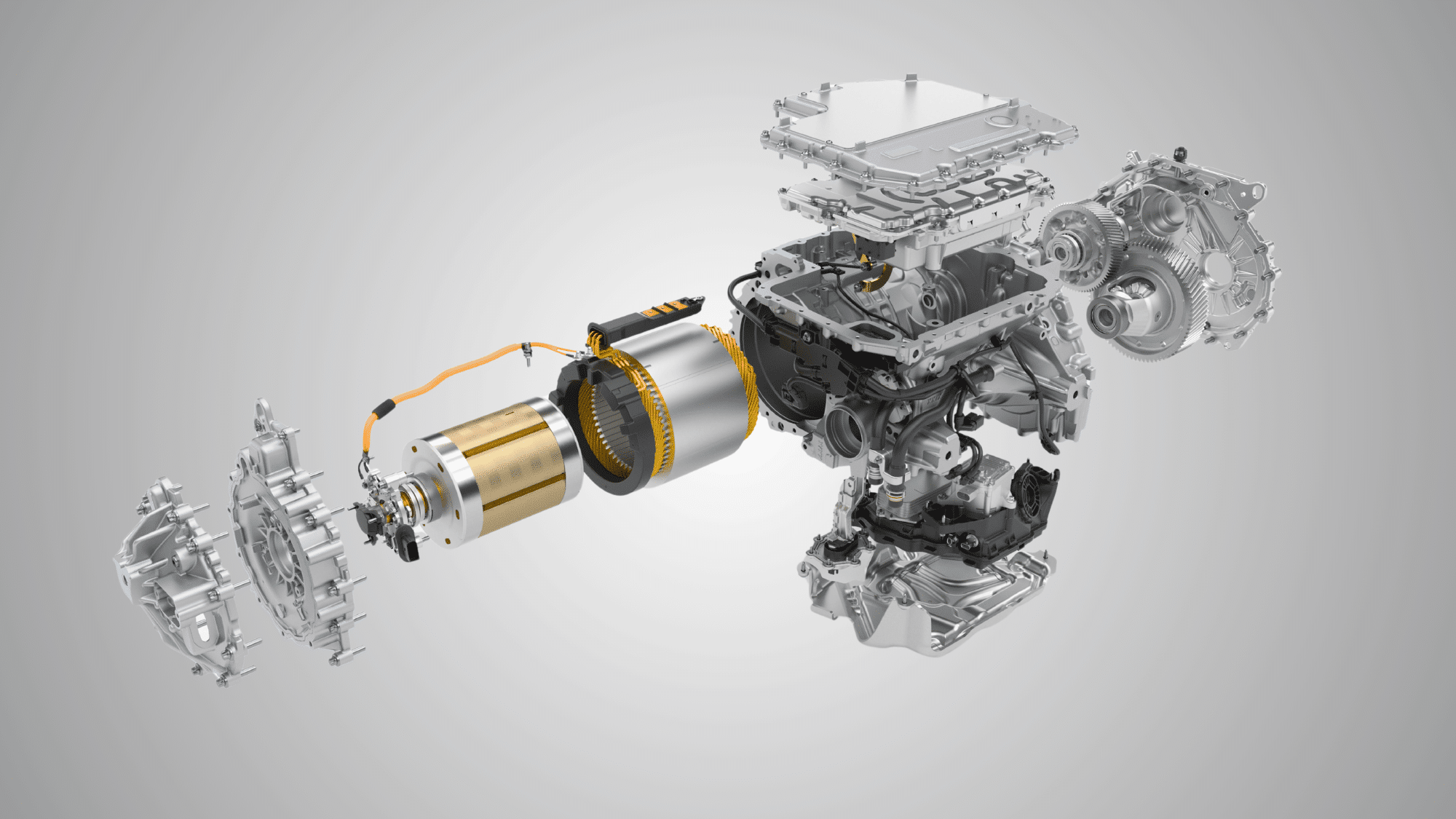

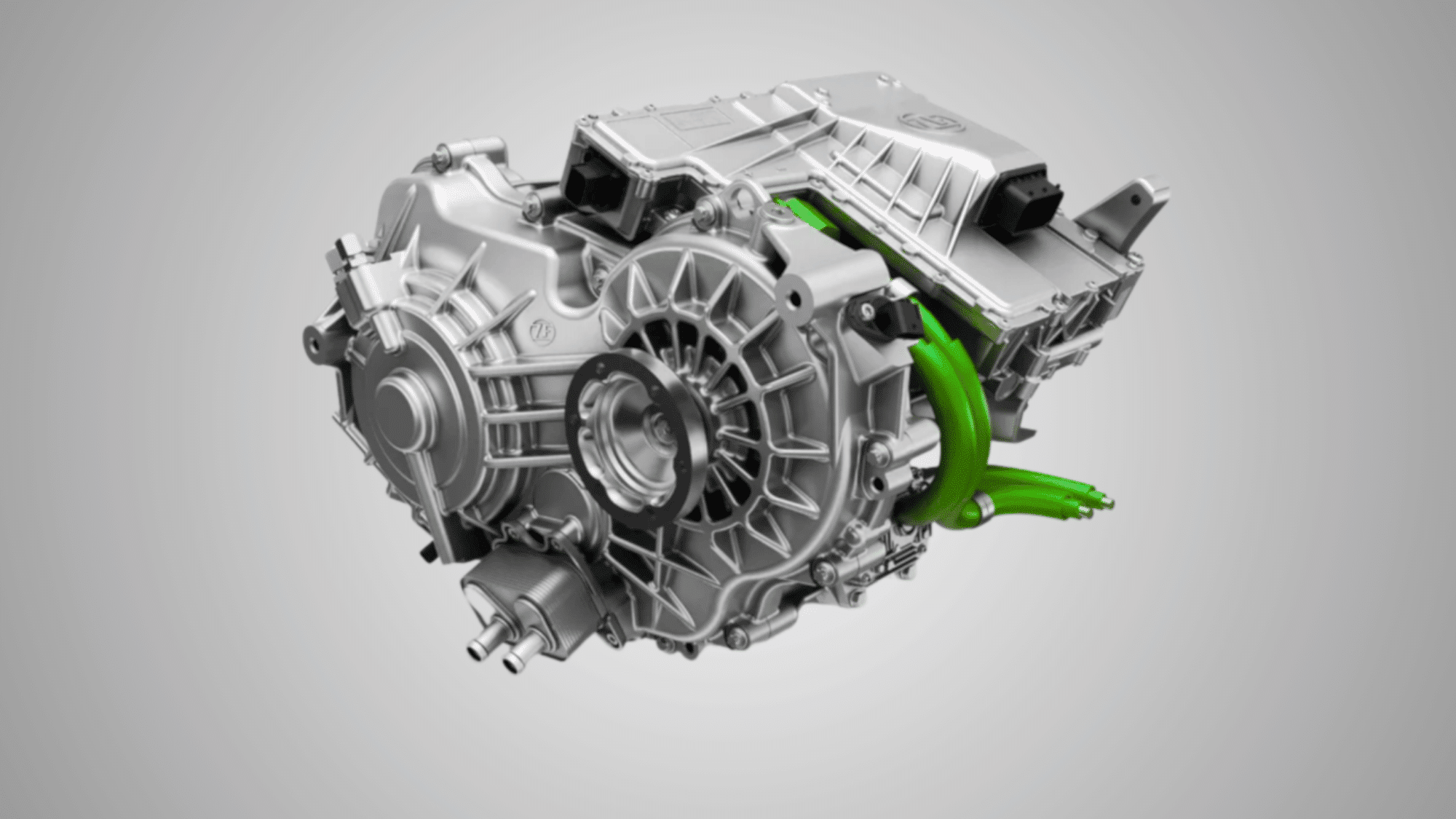

2. Electric Motor

The electric motor converts stored electrical energy from the battery into mechanical rotational force that physically turns the wheels and propels the vehicle forward.

Electric motors generate motion through electromagnetic field interactions, producing instant maximum torque from zero RPM without transmission shifting delays.

Most manufacturers use either AC induction motors or permanent-magnet synchronous motors, depending on performance targets, cost considerations, and efficiency priorities.

The compact motor design enables flexible mounting, often integrated directly into drive axles, achieving operational efficiency exceeding 90% with minimal energy wasted as heat.

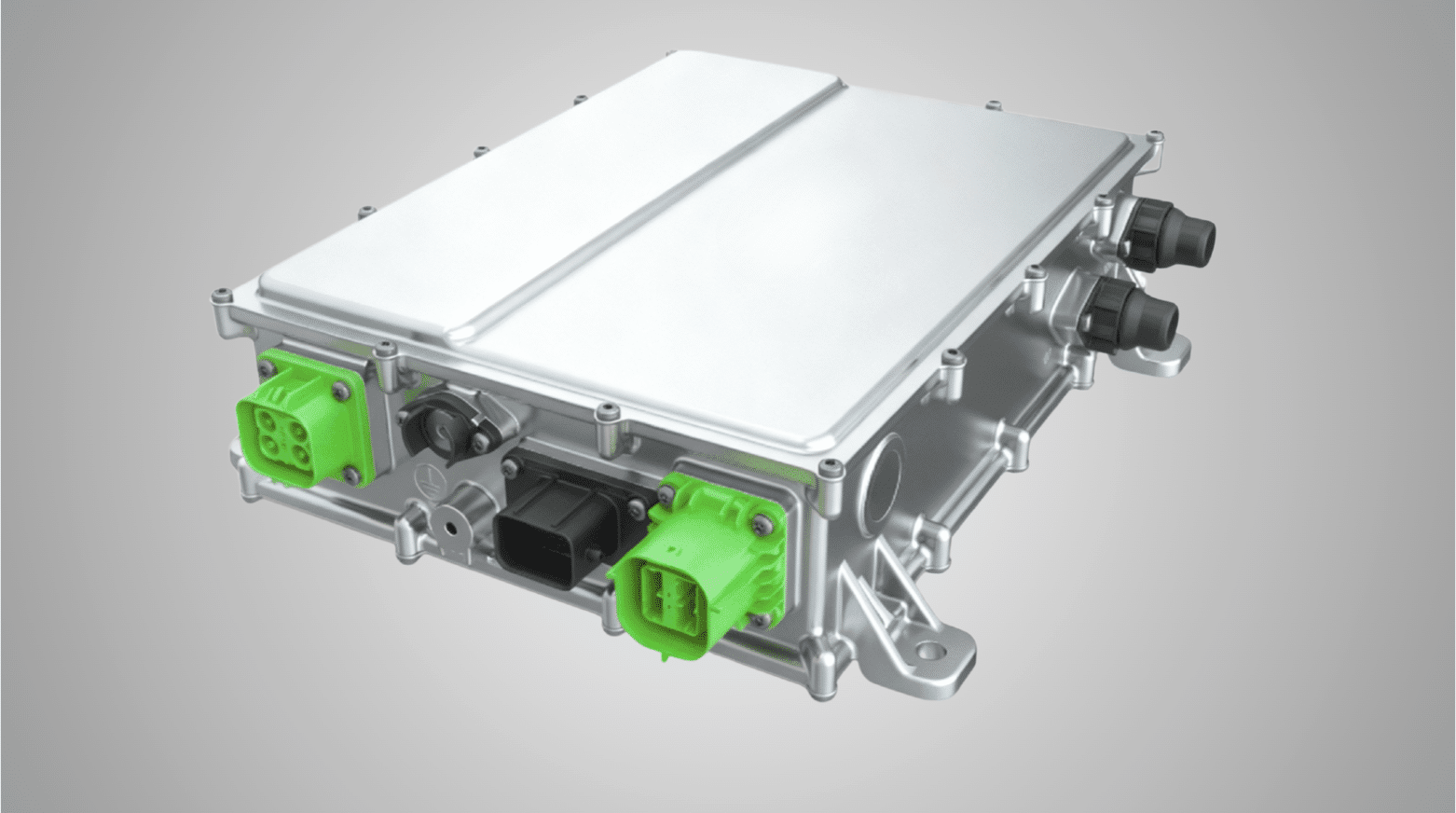

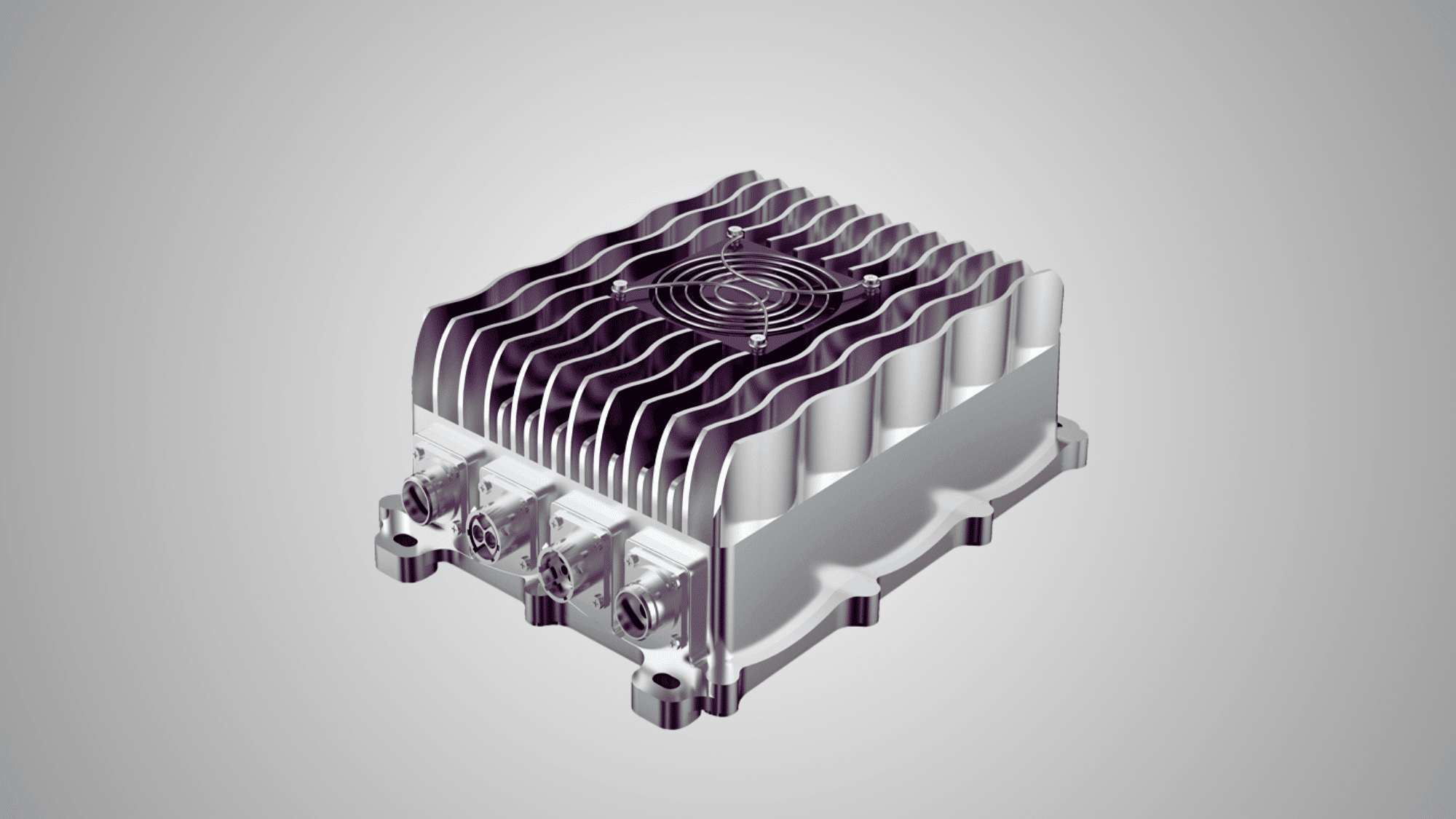

3. Power Electronics Controller

The power electronics controller functions as the smooth electrical traffic director, managing precise power flow between the battery and all vehicle systems with accuracy.

This advanced computer adjusts voltage levels and current delivery thousands of times each second, optimizing performance while protecting from electrical stress or damage.

The controller converts current from the battery into alternating current required by most electric motors, managing braking by reversing current flow to recapture kinetic energy.

Over-the-air software updates enable manufacturers to develop controller algorithms post-purchase, adding features or refining performance without physical modifications.

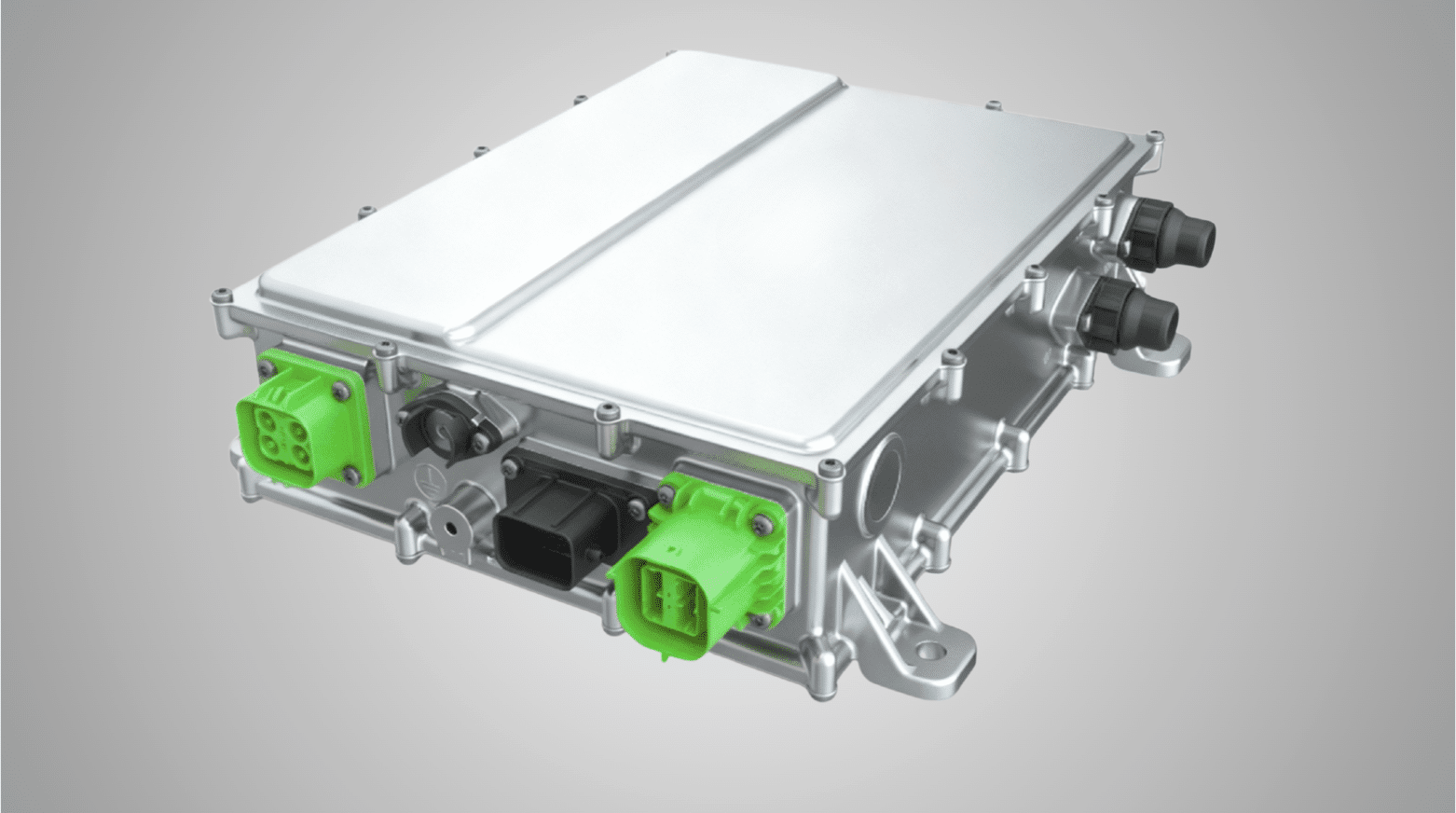

4. Onboard Charger

The onboard charger converts alternating current from external charging sources into direct current suitable for battery storage during a charging session.

This critical component regulates charging speed, voltage levels, and current flow according to battery temperature and available input power to maximize battery longevity.

Higher-capacity chargers enable faster replenishment at Level 2 charging stations, significantly reducing the time required to restore depleted battery capacity for daily use.

The charger communicates with the charging infrastructure, providing optimal power delivery rates while following safety, accepting both 120-volt and 240-volt input.

5. Battery Management System

The battery management system continuously monitors and controls each cell in the battery pack, ensuring balanced performance and maximum lifespan under all conditions.

This smooth electronic system tracks voltage, temperature, and current flow for thousands of cells simultaneously during driving, charging, and rest periods with extreme precision.

It prevents dangerous overcharging or excessive discharge that could permanently damage cells, reduce capacity, or create safety hazards through thermal events.

The system actively balances cells by redistributing charge to maintain uniform voltage levels across the pack.

6. DC-DC Converter

The DC-DC converter steps down high-voltage battery power ranging from 400-800 volts to the standard 12-volt level required by conventional automotive accessories and systems.

This component supplies electricity to lights, power windows, infotainment displays, and other features that would otherwise require expensive redesign for high-voltage operation.

The converter maintains a small 12-volt auxiliary battery providing backup power for critical safety systems like airbags and electronic locks during main battery disconnection.

Efficient power conversion minimizes energy losses while ensuring all comfort, convenience, and safety features function reliably regardless of the main battery state or charge level.

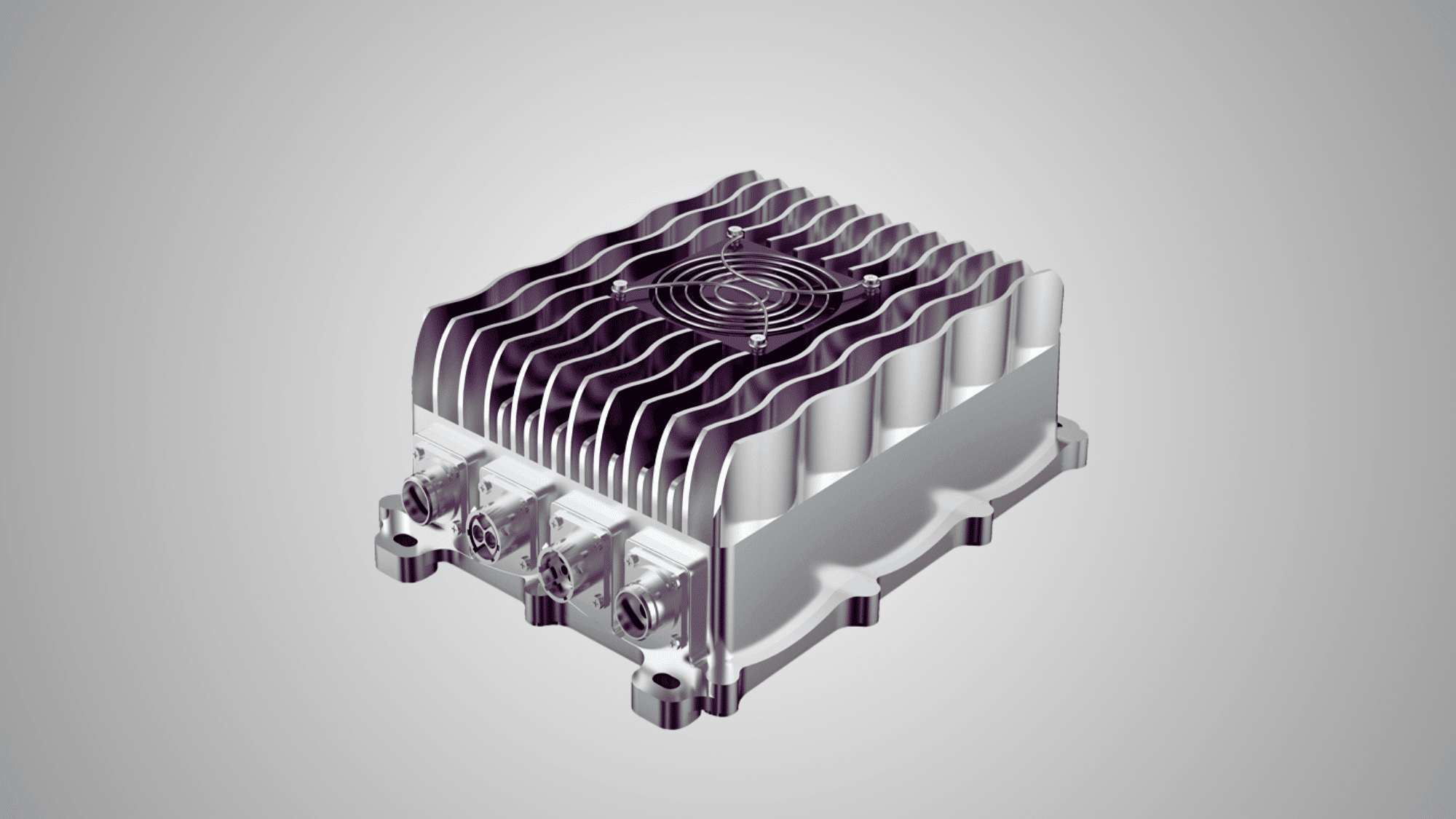

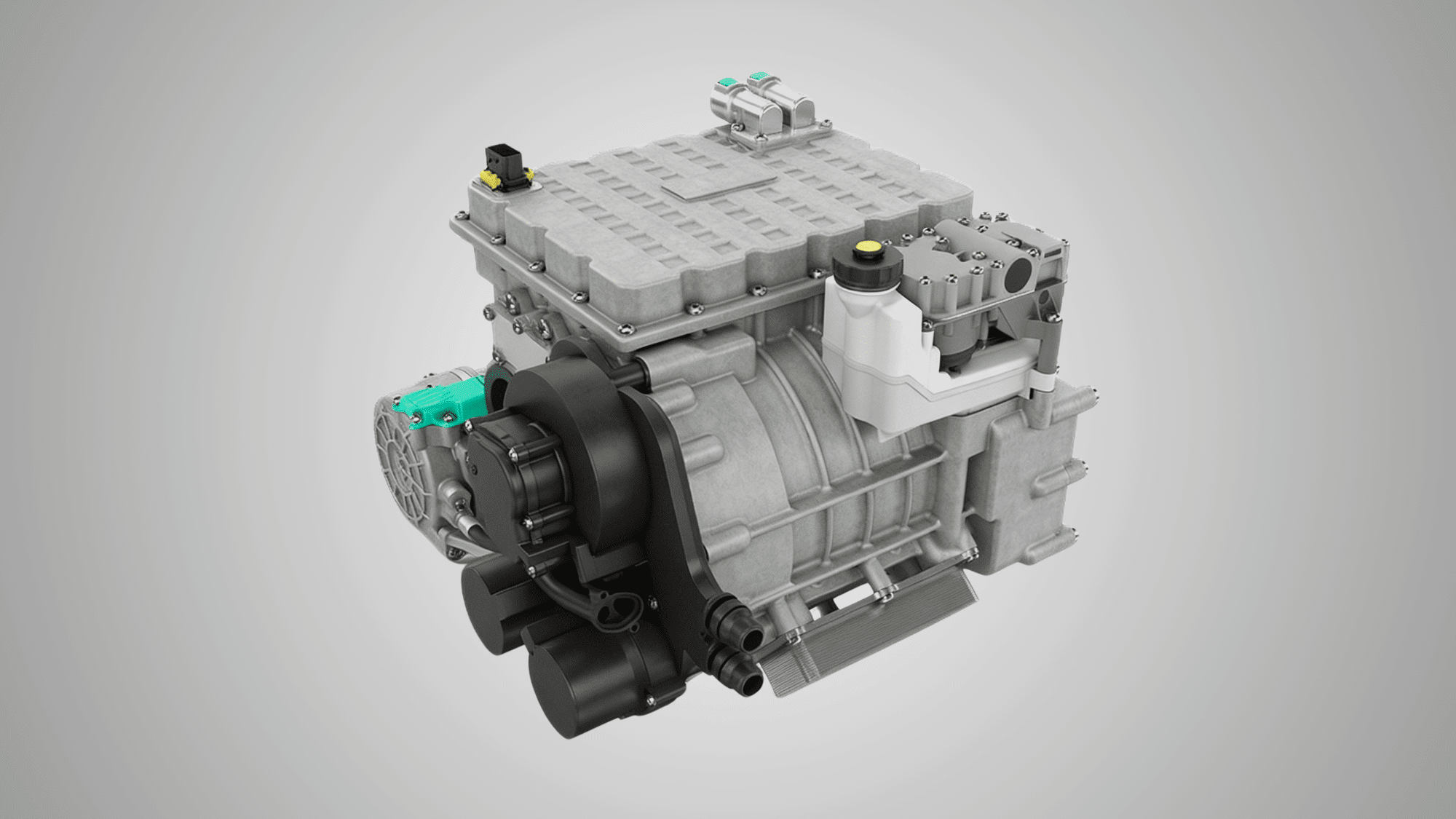

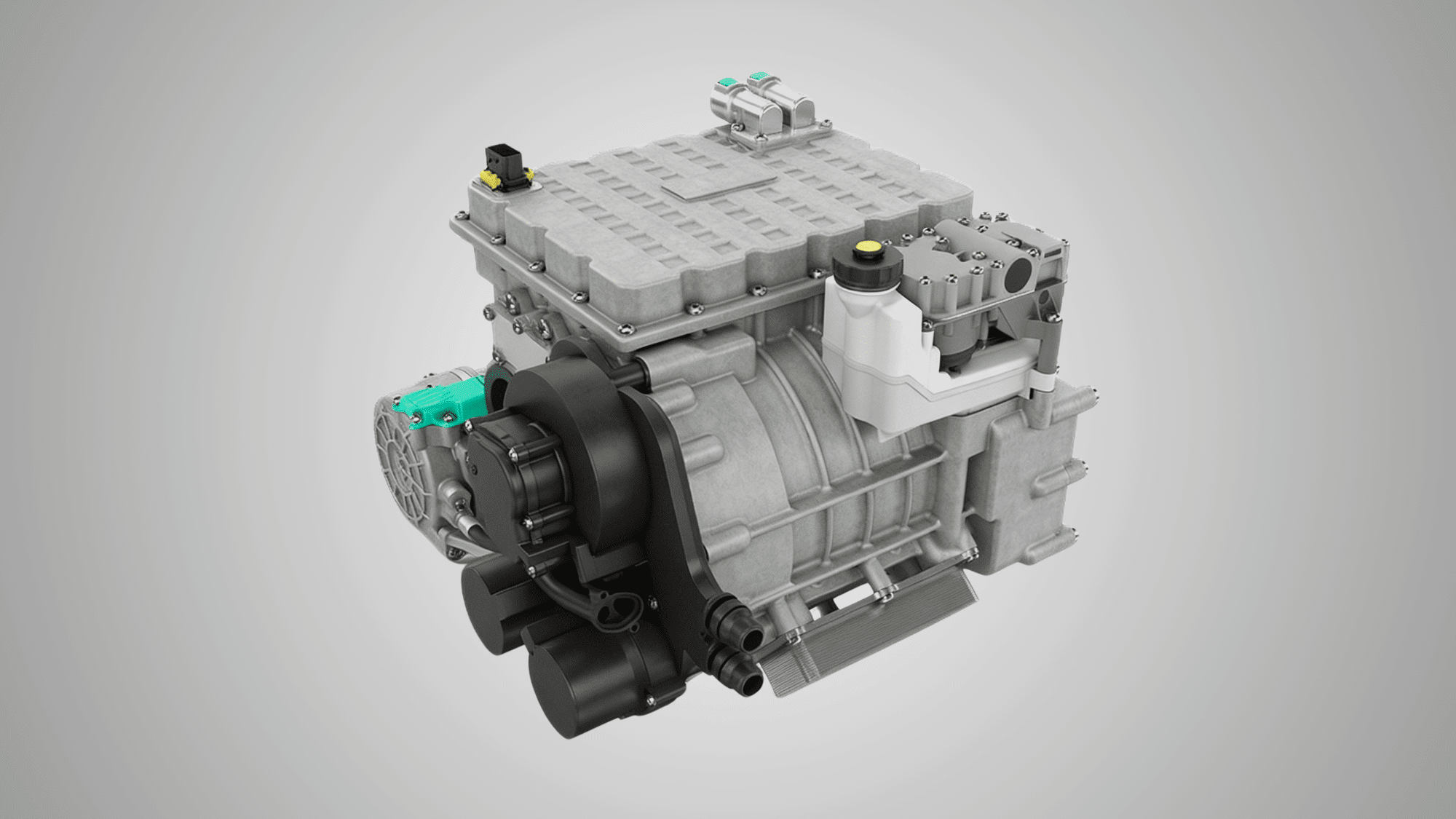

7. Thermal Management System

The thermal management system actively monitors temperatures for the battery pack, electric motor, and power electronics components under all driving and charging conditions.

Liquid-cooling circuits or air-based systems remove excess heat generated during rapid acceleration, sustained high-speed driving, or fast charging sessions that stress components.

Cold-weather heating systems warm batteries to optimal operating temperatures, maximizing available range and charging speed capability in freezing conditions.

Proper thermal management dramatically extends battery lifespan by preventing exposure to extreme temperatures that accelerate the reduction of overall capacity retention.

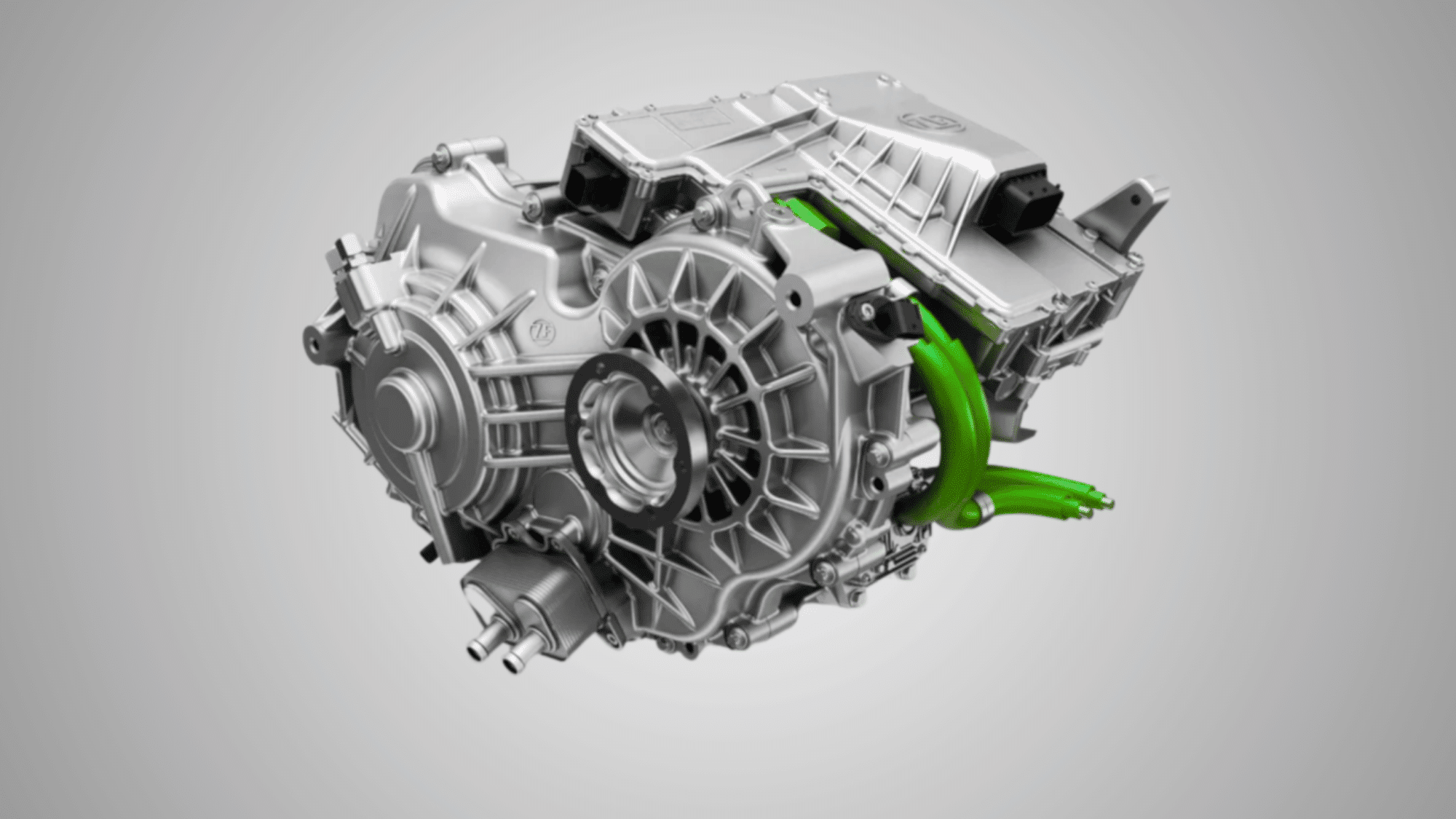

8. Transmission

Electric vehicle transmissions employ simpler designs, typically using single-speed reduction gearing, because electric motors deliver strong torque across wide RPM ranges.

The reduction gear assembly steps down the motor’s extremely high rotation speeds, often exceeding 15,000 RPM, to appropriate wheel rotation rates for vehicle propulsion.

Some high-performance electric vehicles incorporate two-speed transmissions, optimizing acceleration and high-speed cruising simultaneously when maximum performance matters.

The transmission housing contains differential gearing, allowing inside and outside wheels to rotate at different speeds during cornering for stable, predictable handling characteristics.

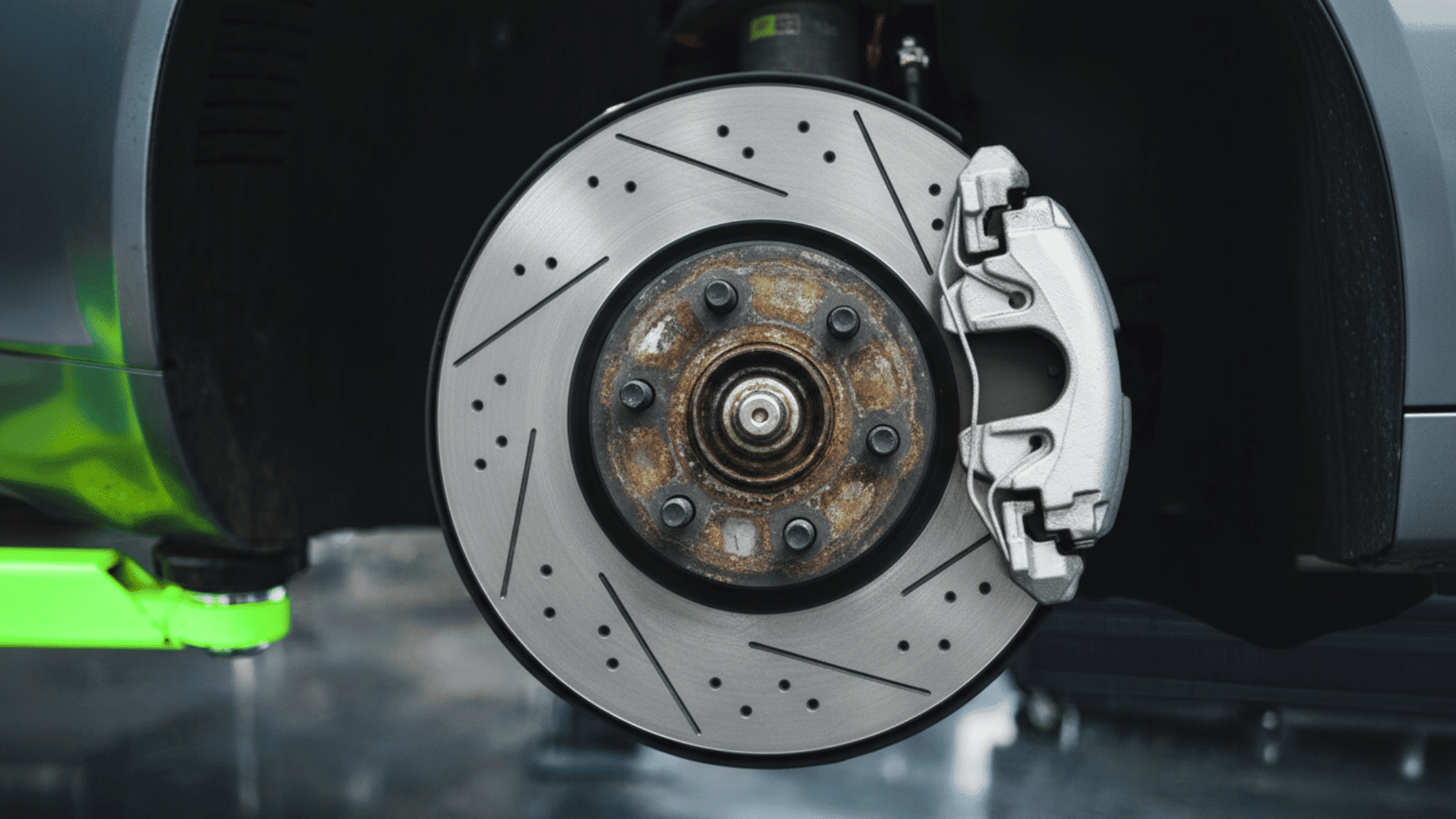

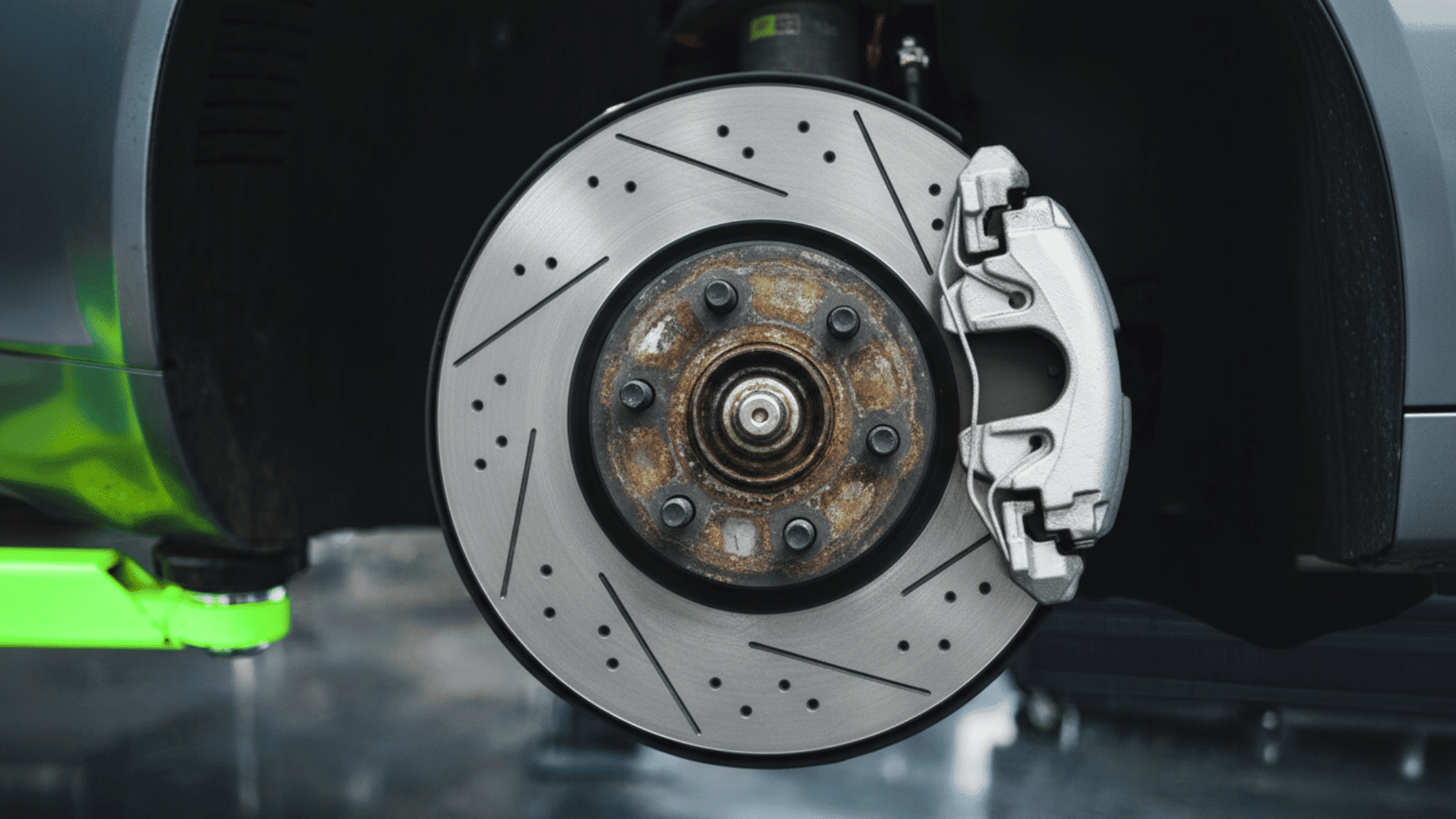

9. Regenerative Brakes

This braking system captures kinetic energy during vehicle deceleration, converting forward motion back into electrical power stored in the battery rather than wasting it as friction heat.

This system reverses the electric motor’s normal operation, creating electromagnetic resistance that slows the vehicle while generating electricity that flows back to the battery.

Recovered energy extends practical driving range by 10-30% depending on driving patterns, terrain, and traffic conditions encountered during typical use.

Smooth computer-blending combines regenerative and conventional friction braking seamlessly, providing smooth, predictable braking while significantly reducing maintenance.

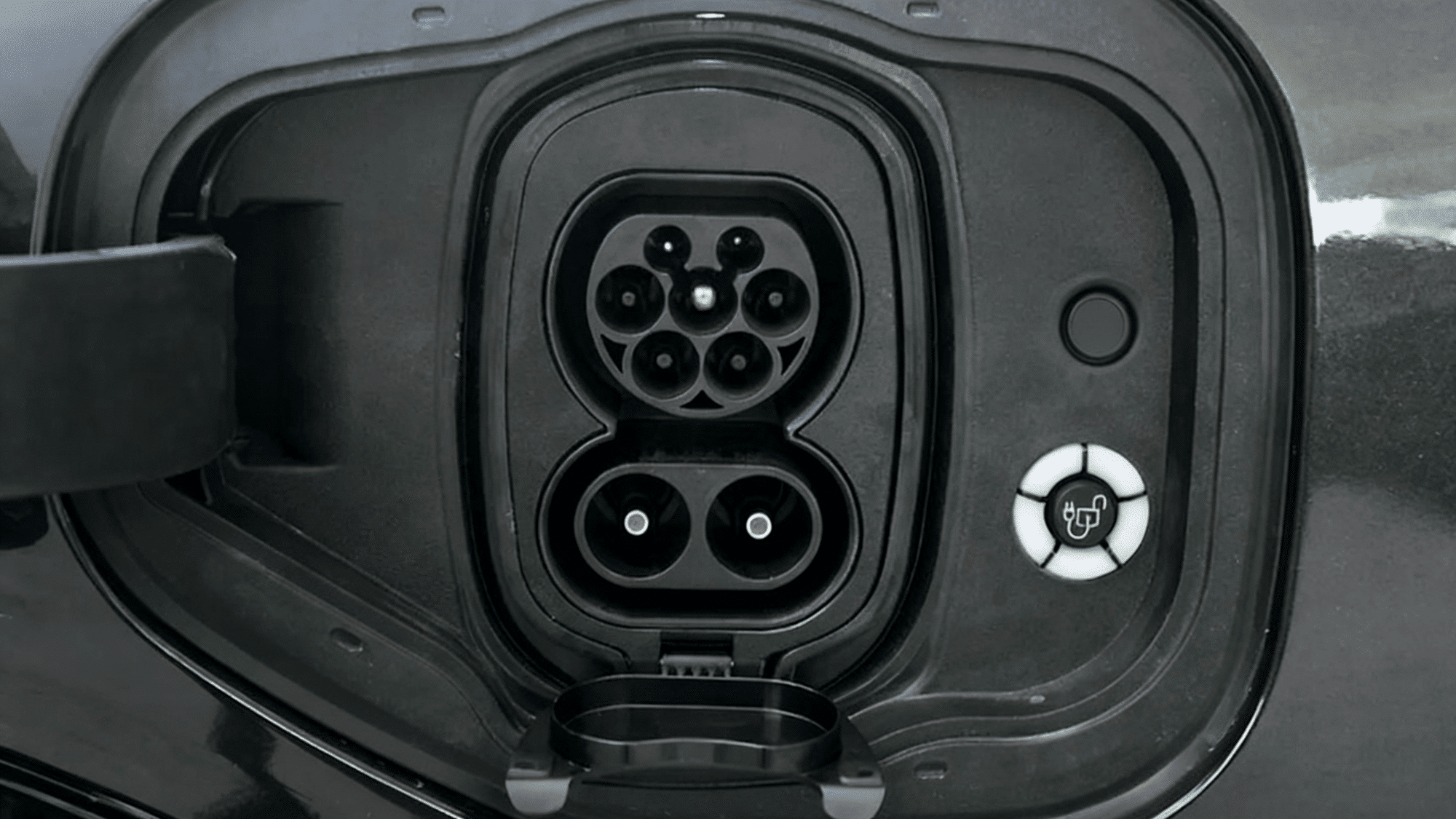

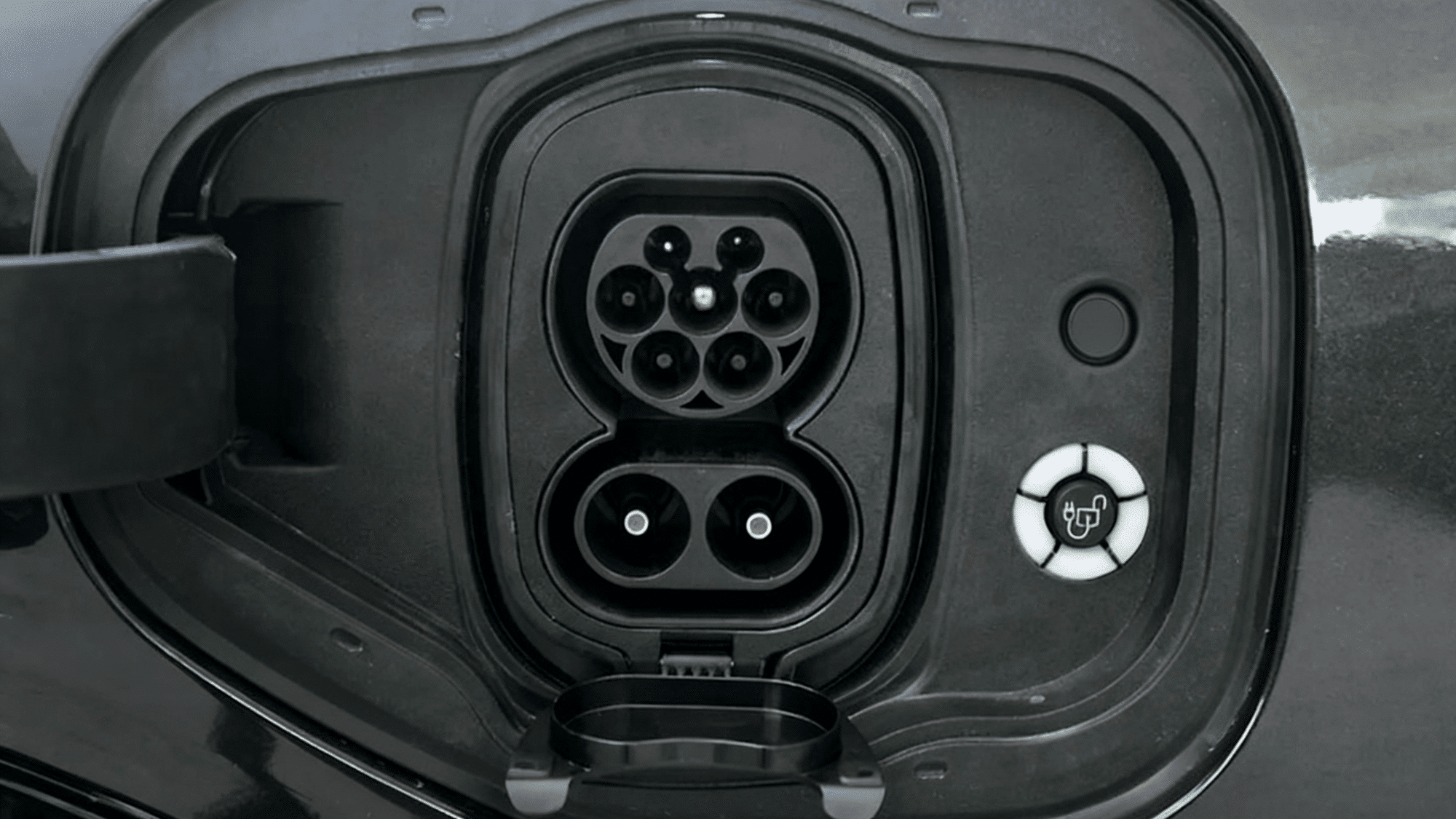

10. Charging Port

The charging port provides the weatherproof physical connection through which external electrical power enters the vehicle, enabling battery refill at home or work charging stations.

Most electric vehicles include ports accommodating multiple charging connector standards like J1772, CCS Combo, or CHAdeMO, depending on regional markets and manufacturers.

The port contains specialized communication pins enabling the vehicle and charging equipment to exchange critical information about battery status and safety parameters.

Secure locking mechanisms prevent accidental cable disconnection or theft of expensive charging equipment, while LED indicators display real-time charging status information.

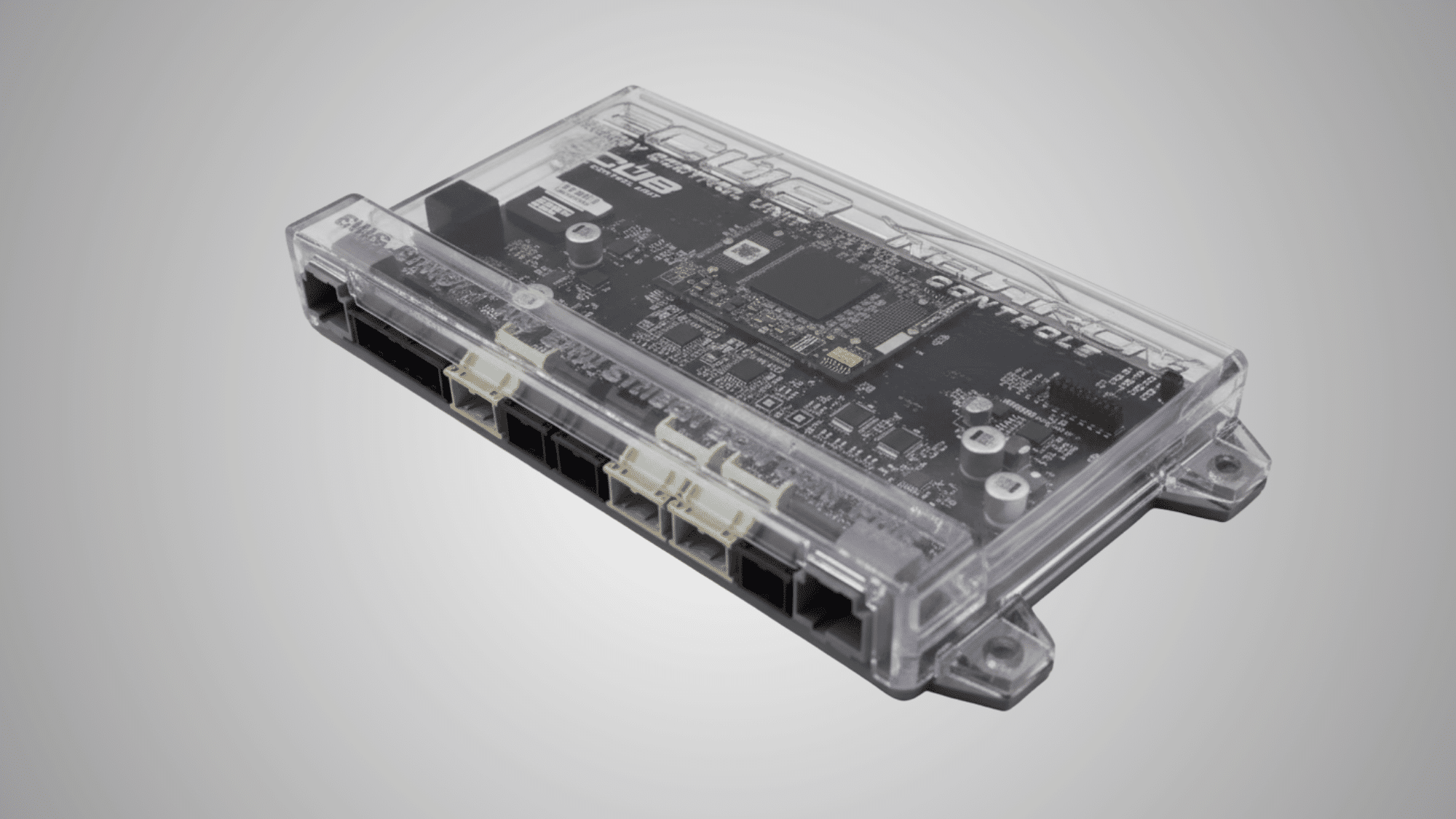

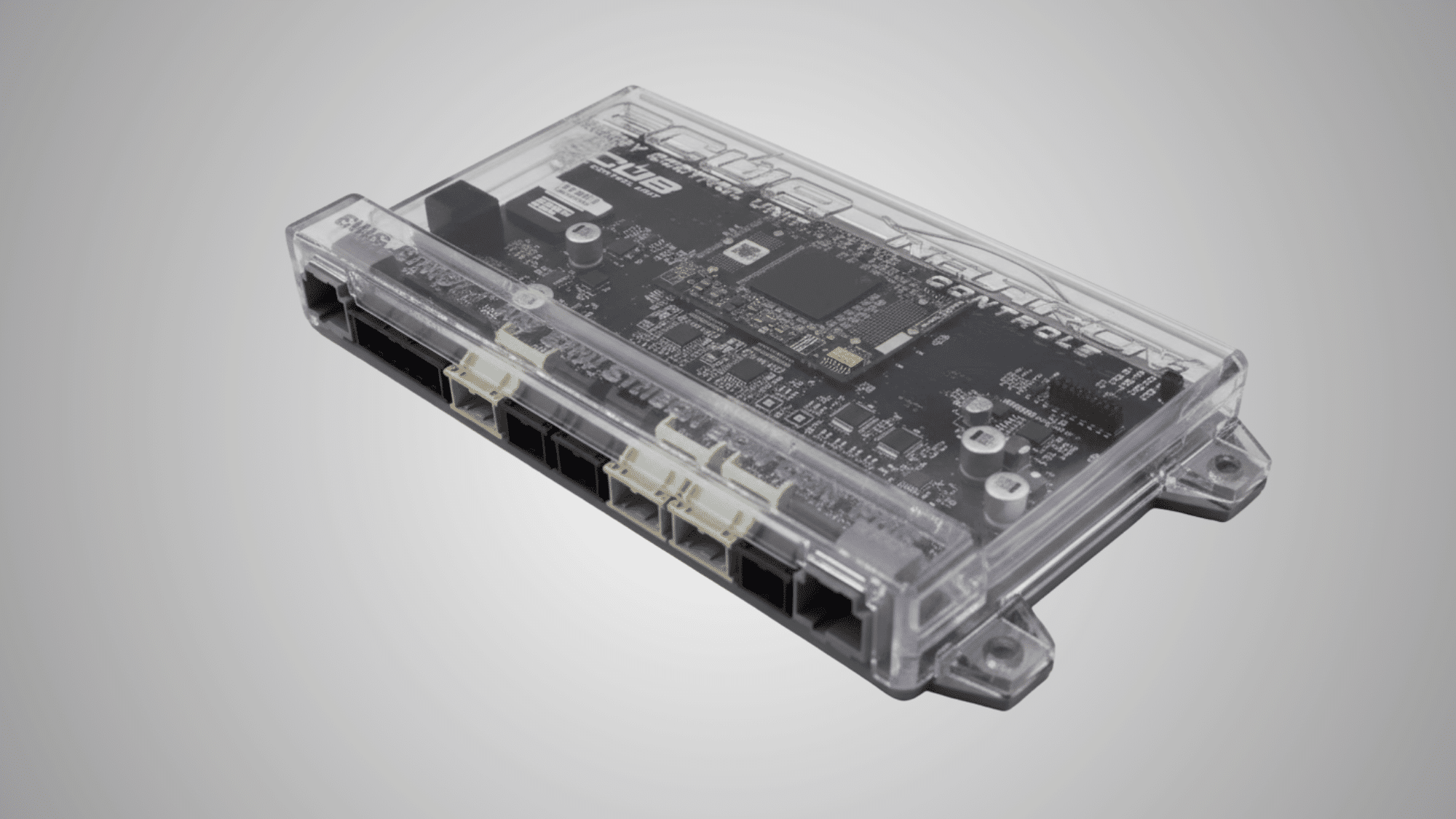

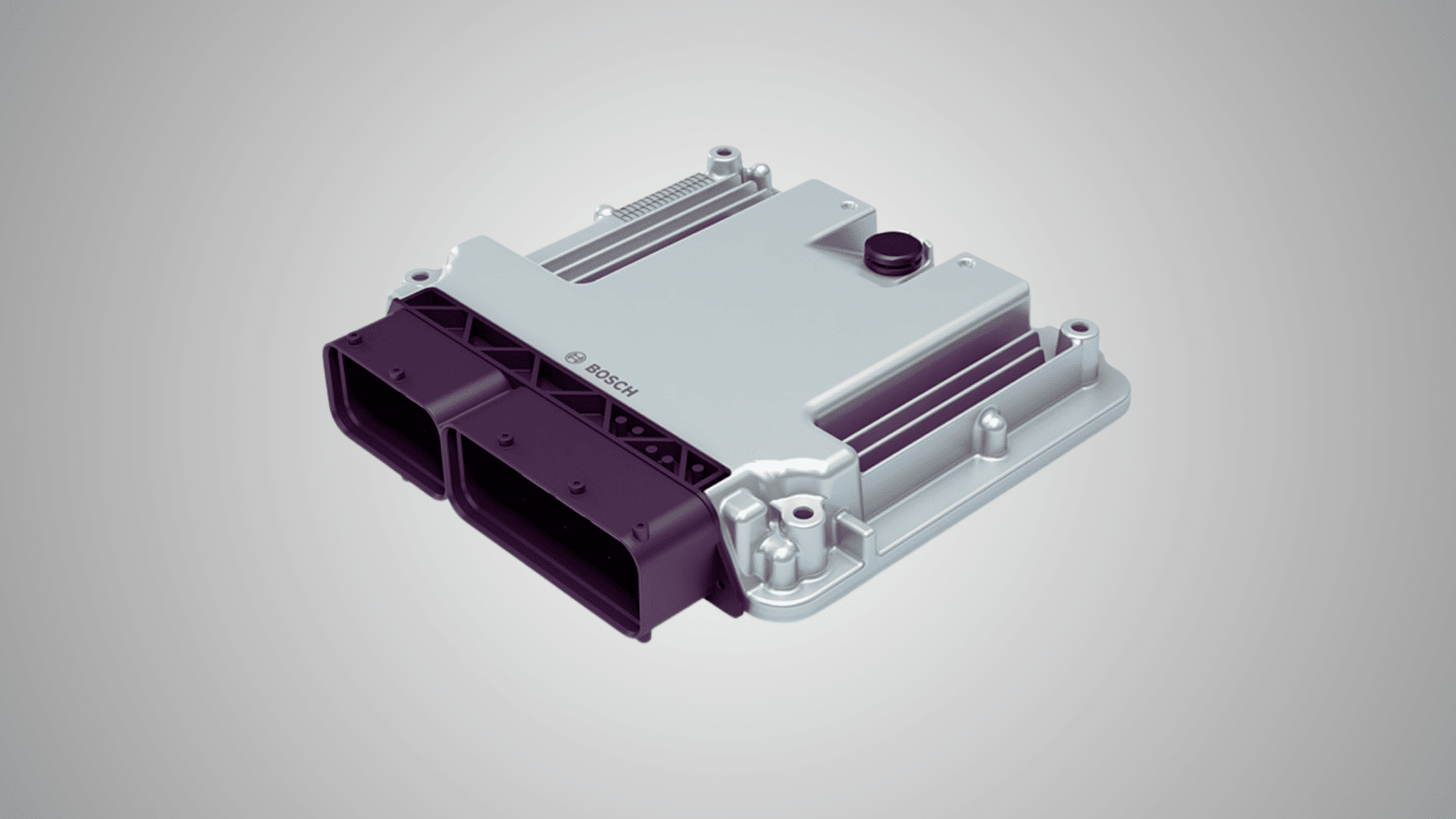

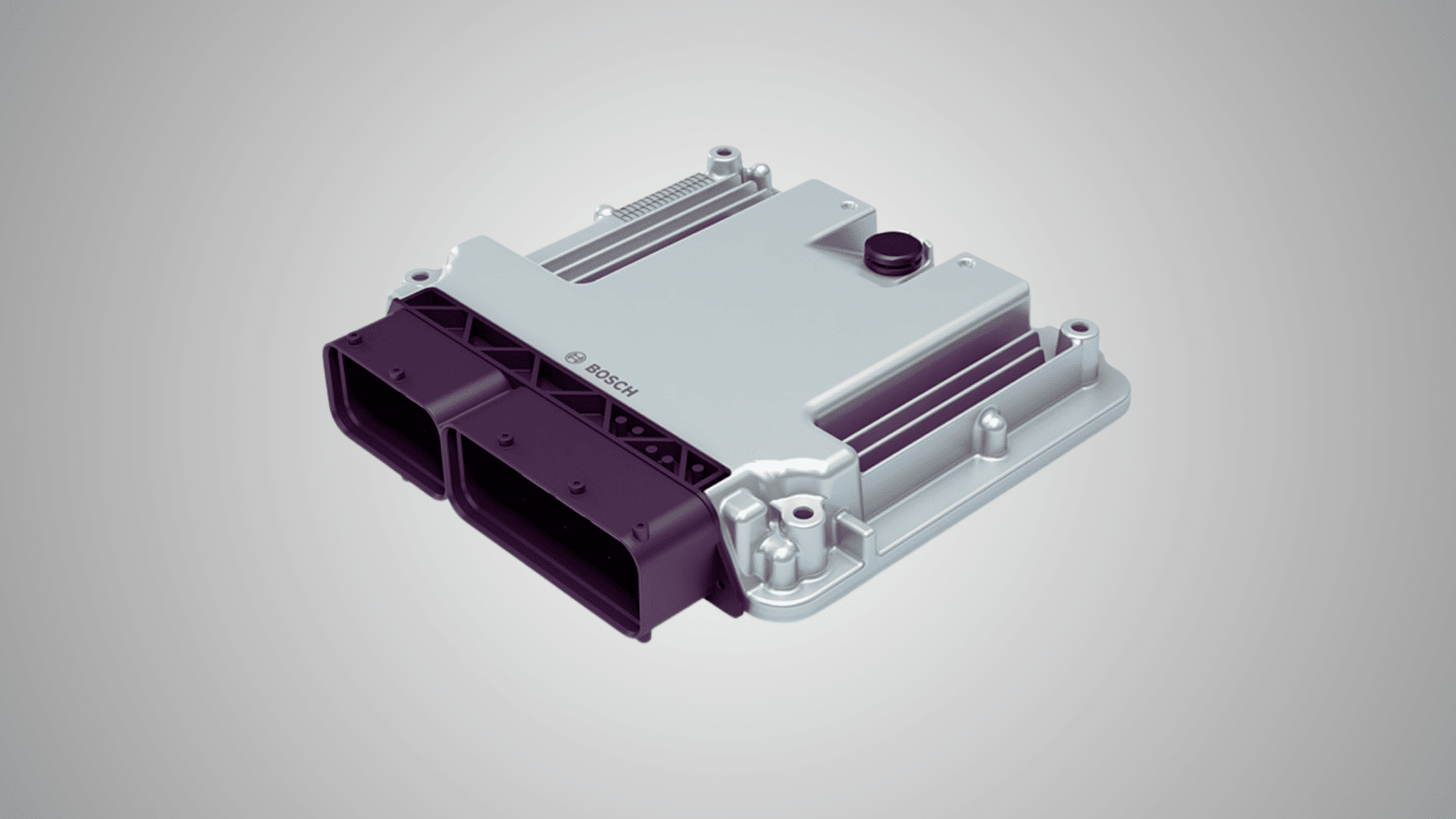

11. Vehicle Control Unit

The vehicle control unit functions as the central computer brain, orchestrating all electric vehicle systems and coordinating complex interactions between dozens of components.

This powerful processor manages power distribution, continuously monitors system health parameters, and dynamically optimizes efficiency based on real-time driving conditions.

It processes information from numerous sensors distributed throughout the vehicle thousands of times per second, making instant decisions that affect performance and safety.

The control unit implements advanced safety features, including traction control, electronic stability management, and adaptive cruise control, protecting occupants through intelligent automated responses.

Auxiliary Systems in Electric Vehicles

Beyond the main propulsion components, electric vehicles include various supporting systems that enhance comfort, safety, and overall functionality for drivers.

- Climate control: HVAC system uses heat pumps for efficient cabin heating and cooling without engine waste heat.

- Power steering: Electric power steering draws minimal battery power while providing responsive handling and parking assistance.

- Brake system: Hydraulic friction brakes work alongside regenerative braking for complete stopping capability in all conditions.

- Lighting system: LED lights throughout the vehicle consume minimal power while providing excellent visibility and distinctive styling.

- Infotainment display: Touchscreen interfaces manage navigation, entertainment, vehicle settings, and charging information for drivers.

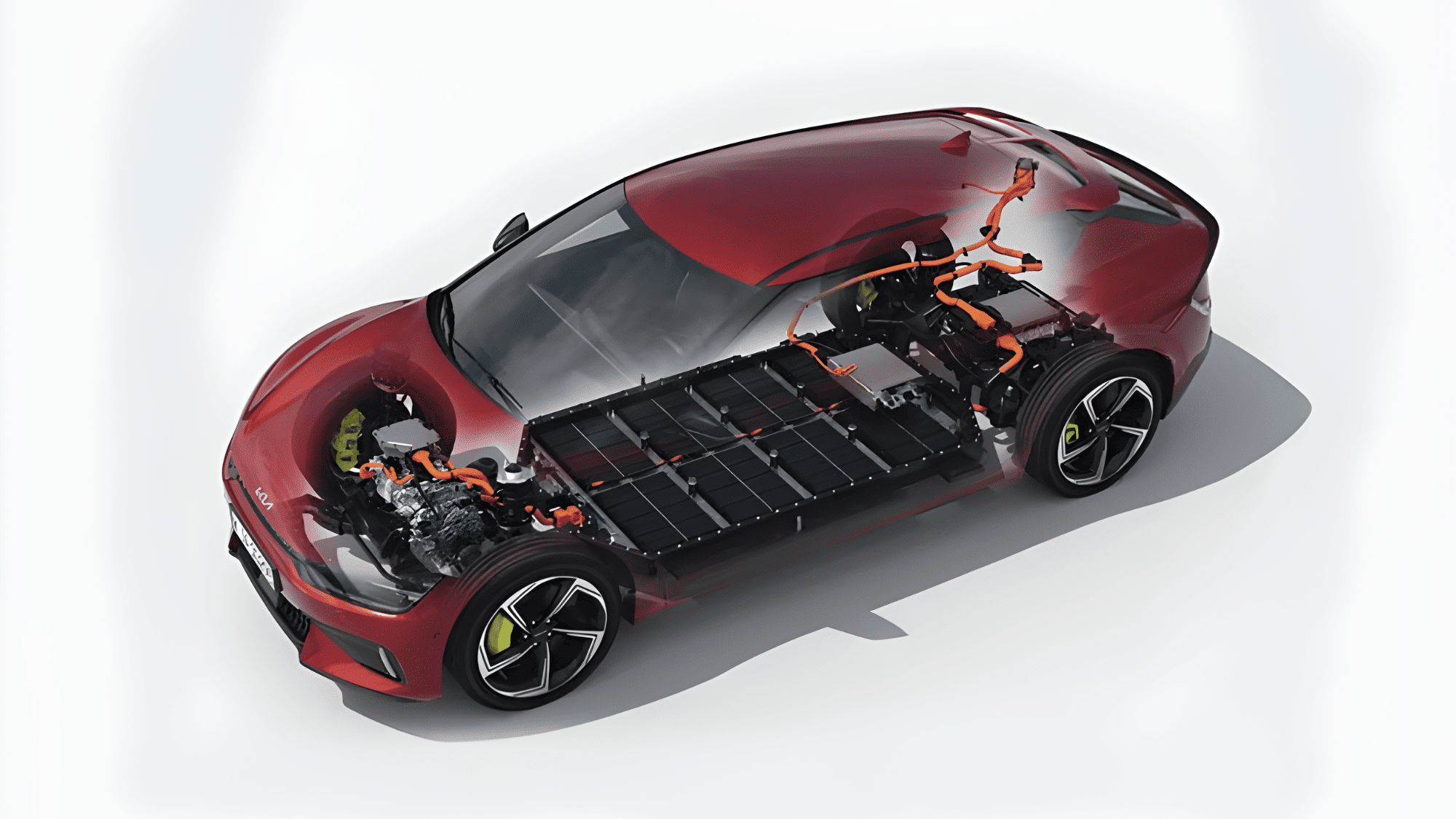

How these Components Work Together in an EV?

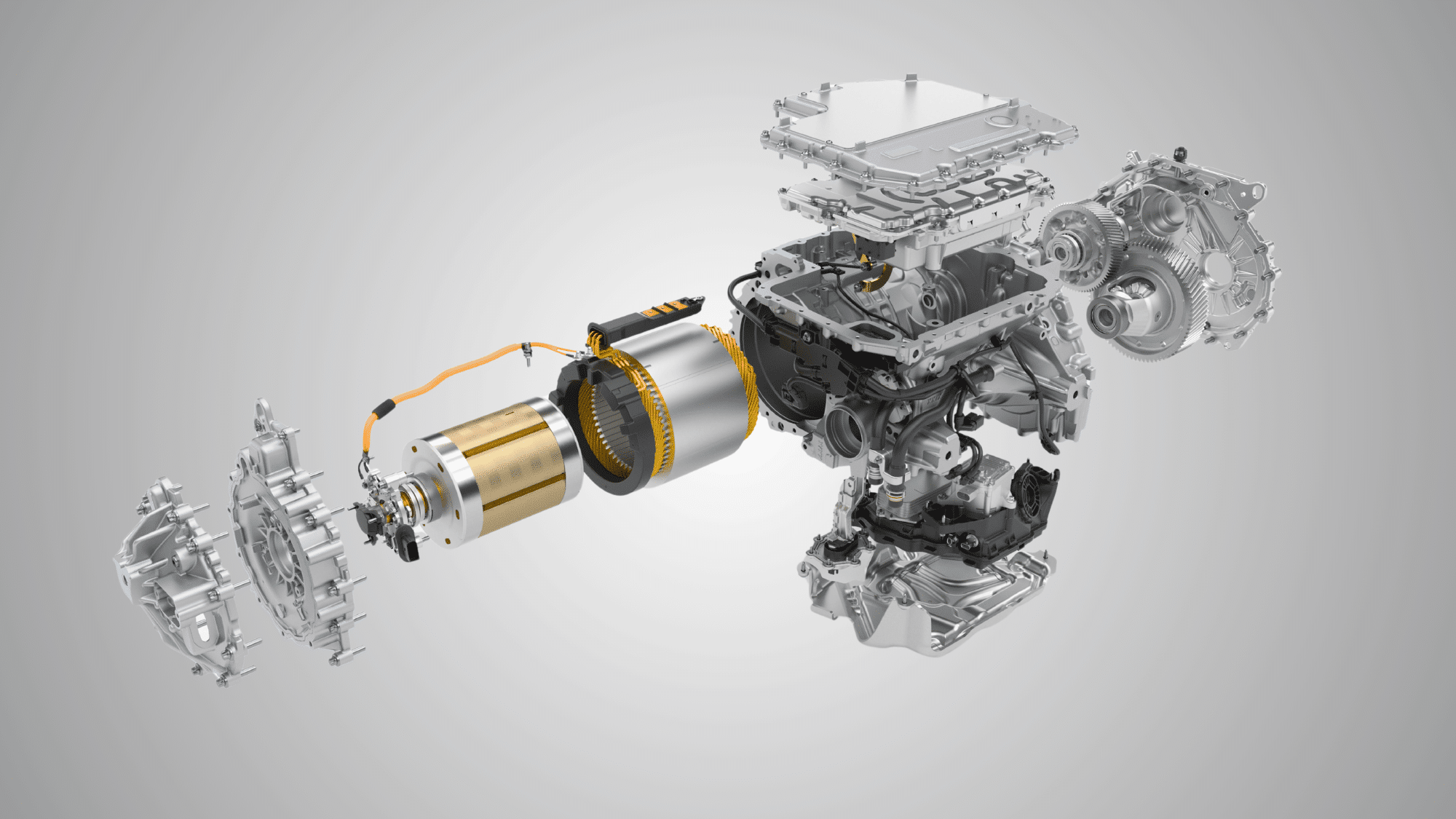

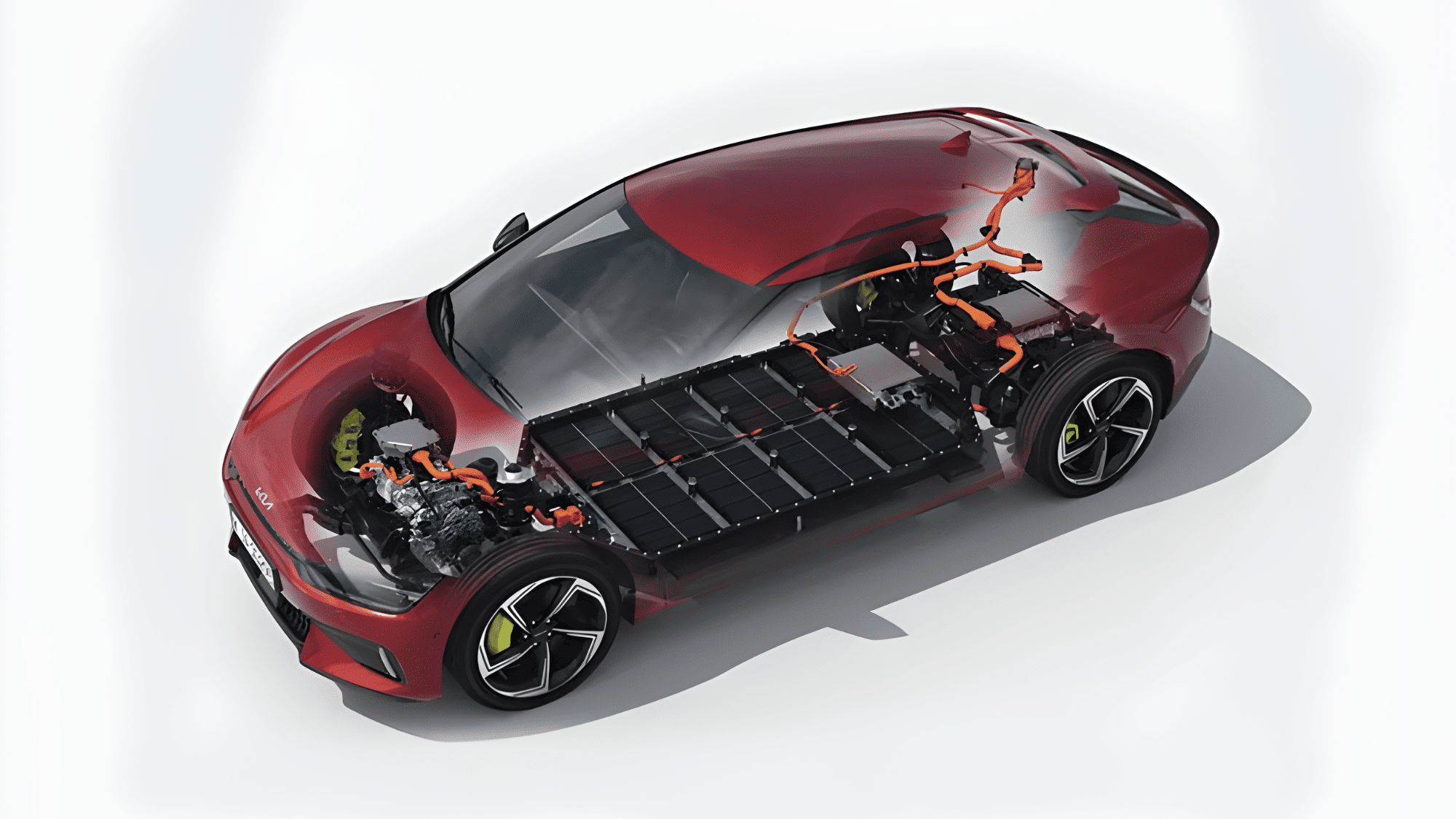

Image Source: Kia

All electric vehicle components function as an integrated system managed by smooth software and control algorithms continuously.

The vehicle control unit coordinates power flow from the battery through the motor controller to the wheels. When you accelerate, the battery management system monitors cell conditions while releasing stored energy safely.

The thermal management system activates cooling or heating as needed to maintain optimal operating temperatures throughout.

During deceleration, the regenerative braking system reverses energy flow, capturing motion and storing it back in the battery.

Charging sessions involve coordination between the onboard charger, battery management system, and external charging station equipment.

Advances in EV Component Technology

Battery technology continues to advance rapidly, with solid-state batteries promising higher energy density and faster charging capabilities.

New motor designs improve efficiency and power output while reducing size and manufacturing costs for automakers. Power electronics using silicon carbide semiconductors handle higher voltages with less energy loss than traditional components.

Wireless charging systems eliminate cables by transferring power through electromagnetic induction between ground pads and vehicles.

Bidirectional charging allows EVs to send power back to homes or the grid during peak demand periods. Integrated cooling systems using heat pumps maximize range by efficiently managing thermal needs across all seasons.

Conclusion

Understanding electric vehicle components reveals the simplicity behind these increasingly popular cars on modern roads.

The battery pack stores energy, the motor converts it to motion, and control systems optimize everything continuously.

Simpler mechanical design compared to gas vehicles means fewer parts, less maintenance, and improved reliability over time.

As electric vehicle adoption grows, these components will become increasingly refined and affordable for all consumers. Consider learning more about EVs by test-driving one to experience these components firsthand.