If you’ve ever wondered what Tesla batteries are made of, you’re not alone. Tesla cars are powered by specialized batteries, which distinguish them from regular cars.

I’m excited to share how these batteries are made and what materials go inside them. Knowing this will help you understand why Teslas can travel such a great distance and charge so quickly.

Tesla utilizes advanced chemistry and intelligent design to construct batteries that power their electric cars efficiently and safely.

In this blog, I’ll explain the main parts of Tesla car batteries and how they work, so you can get a clear picture of what makes Tesla batteries so special.

Tesla’s Battery Technology

Tesla’s electric vehicles utilize advanced lithium-ion batteries that strike a balance between performance, safety, and longevity.

These batteries use compact, energy-dense lithium cells in modules to efficiently store and deliver power.

Depending on the vehicle model, Tesla utilizes distinct battery chemistries to cater to various driving needs and budgets.

| Battery Name | Battery Type / Format | Used In | Key Advantages | Ideal For |

|---|---|---|---|---|

| 1865 (formerly 18650) | Cylindrical | Original Tesla Roadster, Model S, Model X | Reliable, consistent quality, proven design | High-performance and luxury vehicles |

| 2170 | Cylindrical | Model 3, Model Y, Tesla Energy products | Higher capacity, better efficiency, cost-effective | Mass-market EVs and energy storage |

| LFP (Lithium Iron Phosphate) | Prismatic | Some Model 3 and Model Y versions | Safer, cheaper, longer lifespan | Entry-level models and markets focused on affordability |

| 4680 | Cylindrical | Model Y (structural pack), Cybertruck (planned), future Tesla models | Larger cells, higher density, structural use | Next-generation vehicles and advanced EV platforms |

By offering both NCA and LFP battery options, Tesla ensures that each model delivers the perfect mix of performance, safety, and value for drivers worldwide.

How Tesla Batteries are Manufactured?

Tesla’s battery manufacturing process is a blend of advanced engineering, automation, and sustainability.

Each step, from sourcing raw materials to assembling the final battery pack, is carefully designed to maximize performance, efficiency, and longevity.

Step 1: Securing Lithium and Other Raw Materials

Tesla begins by sourcing critical materials like lithium, nickel, cobalt, and aluminum. These materials form the foundation of lithium-ion cells.

The company emphasizes ethical sourcing and has taken steps to reduce reliance on third-party suppliers through its in-house lithium refinery in Texas, which refines lithium for direct use in battery production.

Step 2: Electrode Preparation – Cathode and Anode Fabrication

Next, Tesla creates the two main components of each battery cell:

- Cathode (Positive Electrode): Made from lithium compounds, nickel, or iron phosphate, depending on the chemistry (NCA or LFP).

- Anode (Negative Electrode): Usually composed of graphite or silicon composites.

Both are coated onto thin metal foils, dried, and precisely rolled to ensure consistent energy storage and output.

Step 3: Cell Assembly – Layering, Electrolyte Infusion, and Sealing

In this stage, the prepared electrodes are layered or rolled into cylindrical shapes, separated by a micro-thin membrane.

An electrolyte solution is then added, allowing lithium ions to move between the anode and cathode during charging and discharging. Finally, each cell is sealed in a metal casing to protect against leaks and contamination.

Step 4: Module Groupings and Battery Pack Assembly

Individual cells are grouped into modules, which are then connected to form a complete battery pack. Tesla uses automated systems to ensure precise alignment and secure electrical connections.

The packs are equipped with cooling systems, sensors, and safety circuits to manage temperature and performance during operation.

Step 5: Structural Integration and Final Innovations

Tesla has redefined battery design with its structural battery pack, where the battery is integrated directly into the vehicle’s chassis. This innovation improves vehicle rigidity, reduces weight, and enhances safety.

Combined with its in-house lithium refining and material recycling capabilities, Tesla continues to advance toward a more sustainable and efficient battery production ecosystem.

Materials and Components Used in Tesla Batteries

Tesla’s battery design combines cutting-edge chemistry with precision engineering. Each component plays a vital role in delivering the performance, safety, and longevity that Tesla vehicles are known for.

Cathode

Tesla uses two main cathode chemistries based on vehicle type:

- NCA (Nickel-Cobalt-Aluminum): Used in long-range vehicles like the Model S and Model X, offering higher energy density and extended driving range.

- LFP (Lithium-Iron-Phosphate): Found in standard-range Model 3 and Model Y versions, providing safer operation, lower cost, and longer life cycles.

Anode

The anode is primarily made of graphite, with silicon enhancementsadded to improve capacity and charging speed.

This combination helps Tesla achieve faster charging and higher energy output without compromising battery health.

Electrolyte

Tesla’s batteries rely on a carefully formulated electrolyte solution made of lithium salts (typically LiPF₆) dissolved in a blend of organic solvents.

This liquid medium enables lithium ions to move swiftly between the anode and cathode during charge and discharge cycles.

The purity and stability of the electrolyte are crucial for maintaining battery performance, safety, and lifespan over thousands of cycles.

Separator

The separator in Tesla’s battery cells is a thin, porous polymer membrane, often composed of PVDF (polyvinylidene fluoride) or similar advanced materials.

Its primary role is to prevent direct contact between the anode and cathode, avoiding short circuits, while allowing lithium ions to pass freely.

Tesla designs its separators for maximum thermal stability and durability under demanding conditions.

Current Collectors

In Tesla batteries, current collectors play a crucial role in efficiently conducting electricity within each cell. Aluminum foil is used for the cathode, while copper foil serves the anode.

These lightweight, conductive materials ensure smooth current flow, heat dissipation, and structural integrity, contributing to the overall efficiency and reliability of Tesla’s battery architecture.

Battery Casing

Each battery cell is enclosed in a steel or aluminum housing to protect it from mechanical stress, vibration, and temperature variations.

This durable casing also helps in maintaining the integrity of the pack over thousands of charge cycles.

How Tesla Batteries Work: A Simple Explanation

Tesla’s batteries work on the same basic principle as other lithium-ion batteries, but with advanced engineering that boosts performance and efficiency. Inside each cell, lithium ions move between the anode and cathode through the electrolyte.

-

When Charging: Lithium ions travel from the cathode to the anode, where they’re stored until the battery is used.

-

When Discharging (driving): The ions move back from the anode to the cathode, generating an electric current that powers the vehicle’s motor and systems.

This back-and-forth movement of ions creates a steady flow of electricity, which is what enables Tesla cars to run smoothly and efficiently.

Recent Innovations in Tesla EV Battery

Tesla continues to push the boundaries of battery technology with innovative solutions that focus on improving performance, reducing costs, increasing sustainability, and integrating batteries more closely with vehicle design.

Here are some key advancements shaping the future of Tesla batteries.

1. Cobalt-Free and Reduced-Cobalt Batteries

Tesla is moving towards batteries with reduced or no cobalt to address ethical concerns and improve sustainability.

By minimizing cobalt, a material often associated with problematic mining practices, Tesla aims to make its batteries more environmentally responsible while maintaining high energy capacity and safety.

- Reduces dependency on scarce and controversial minerals.

- Supports Tesla’s commitment to environmental and social responsibility.

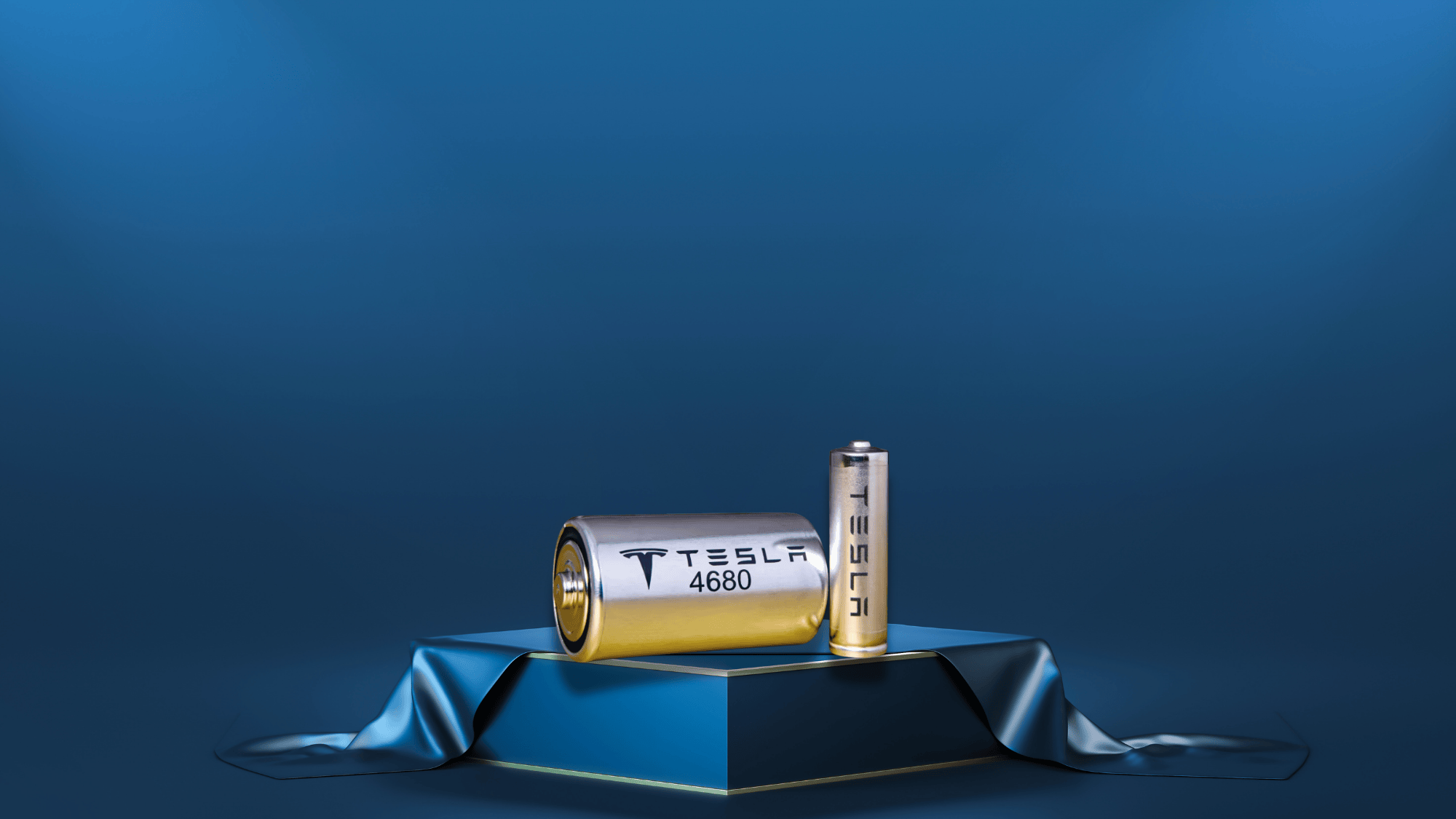

2. Introduction of 4680 Battery Cells

The new 4680 battery cells are larger, cylindrical cells that offer higher energy density, improved thermal management, and lower production costs.

These cells feature a unique tableless design that enhances current flow and heat dissipation, making them more efficient and safer under high-power conditions.

- Enables longer driving ranges and faster charging.

- Used in vehicles like the Cybertruck and select Model Y versions.

3. Structural Battery Packs Integrating with Vehicle Chassis

Tesla’s creative design now includes battery packs that are integrated into the vehicle’s structure.

This integration reduces weight, improves vehicle rigidity, and creates more space inside the car, enhancing overall efficiency and performance.

- Lowers vehicle weight for better range.

- Simplifies vehicle design and manufacturing.

These advancements underscore Tesla’s leadership in battery technology, with a focus on efficiency, cost-effectiveness, and sustainability to power the future of electric vehicles.

Where Does Tesla Source Lithium for Its Batteries?

Tesla sources lithium from multiple regions worldwide to meet its growing battery production needs. The key suppliers come from countries rich in lithium deposits, ensuring a steady and diversified supply chain.

To strengthen its control over critical materials, Tesla has invested in its own lithium refining capabilities, including a large refinery in Texas that aims to produce 50 GWh of battery-grade lithium annually.

Major Lithium Sources

| Region | Key Lithium Sources | Partner Companies / Suppliers |

|---|---|---|

| Australia | Spodumene concentrate (hard rock lithium ore) | Liontown Resources, Pilbara Minerals, Core Lithium |

| South America | Lithium brine deposits (“Lithium Triangle”) | SQM (Chile), Livent (Argentina), Allkem (Argentina/Bolivia) |

| North America | Local lithium mining and refining projects | Piedmont Lithium (USA), Lithium Americas, Albemarle Corporation |

Sustainable and Ethical Practices

Tesla prioritizes responsible mining and ethical sourcing by auditing suppliers, supporting community development, and using cleaner extraction methods.

The company is also advancing recycling technologies to reduce reliance on virgin lithium, supporting a circular battery economy.

This global and sustainable approach ensures Tesla can scale production while minimizing environmental and social impacts.

At the End

Tesla’s batteries are more than just powerful energy sources; they’re the heart of what makes every Tesla efficient, safe, and long-lasting.

From the raw materials to the smart engineering behind each cell, every detail is designed to deliver top performance while supporting sustainability.

I find it interesting how Tesla keeps improving its technology to make electric driving more practical for everyone. As the company continues to innovate, its batteries will only get smarter and greener over time.

If you enjoyed learning about how Tesla batteries work and what makes them special, check out more of the blogs on the website for simple, clear explanations of the latest tech and energy innovations.