Ever think about how electric cars capture energy that regular vehicles waste as heat? Regenerative braking represents one of the smartest technologies in modern electric and hybrid vehicles today.

This system converts your car’s kinetic energy into stored electrical energy during deceleration, rather than losing it.

Understanding how regenerative braking works helps you appreciate the efficiency gains that electric vehicles achieve daily.

Traditional brakes convert motion into heat through friction, essentially throwing away valuable energy with every stop.

This innovative technology extends driving range, reduces brake wear, and makes electric vehicles more practical for everyday use.

What are Regenerative Brakes & How are they Designed?

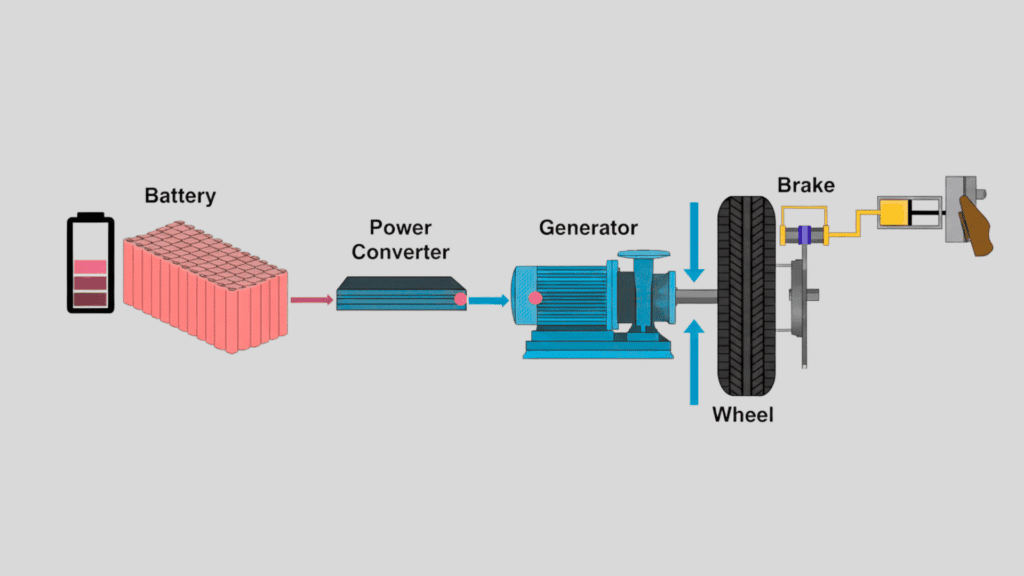

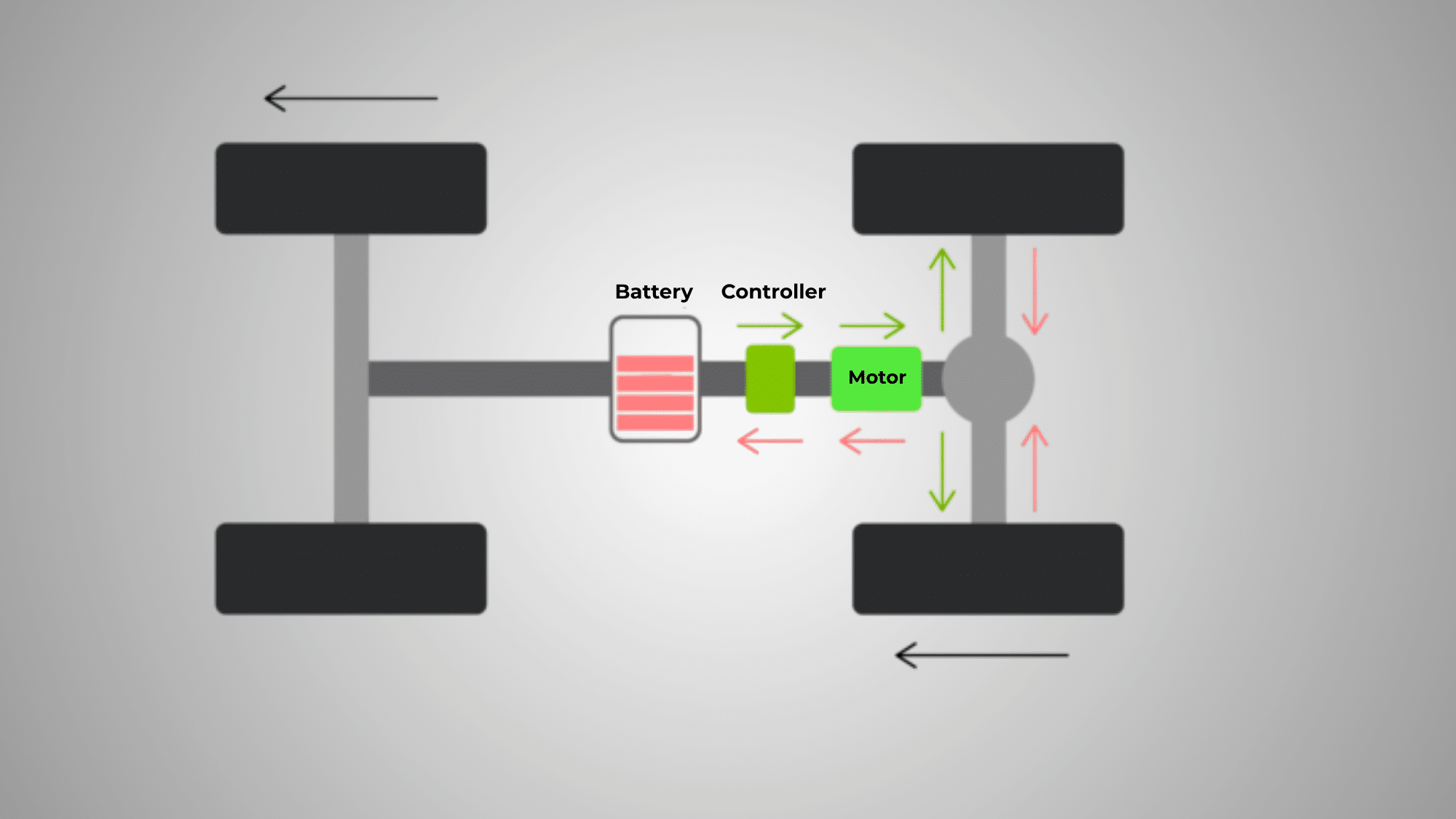

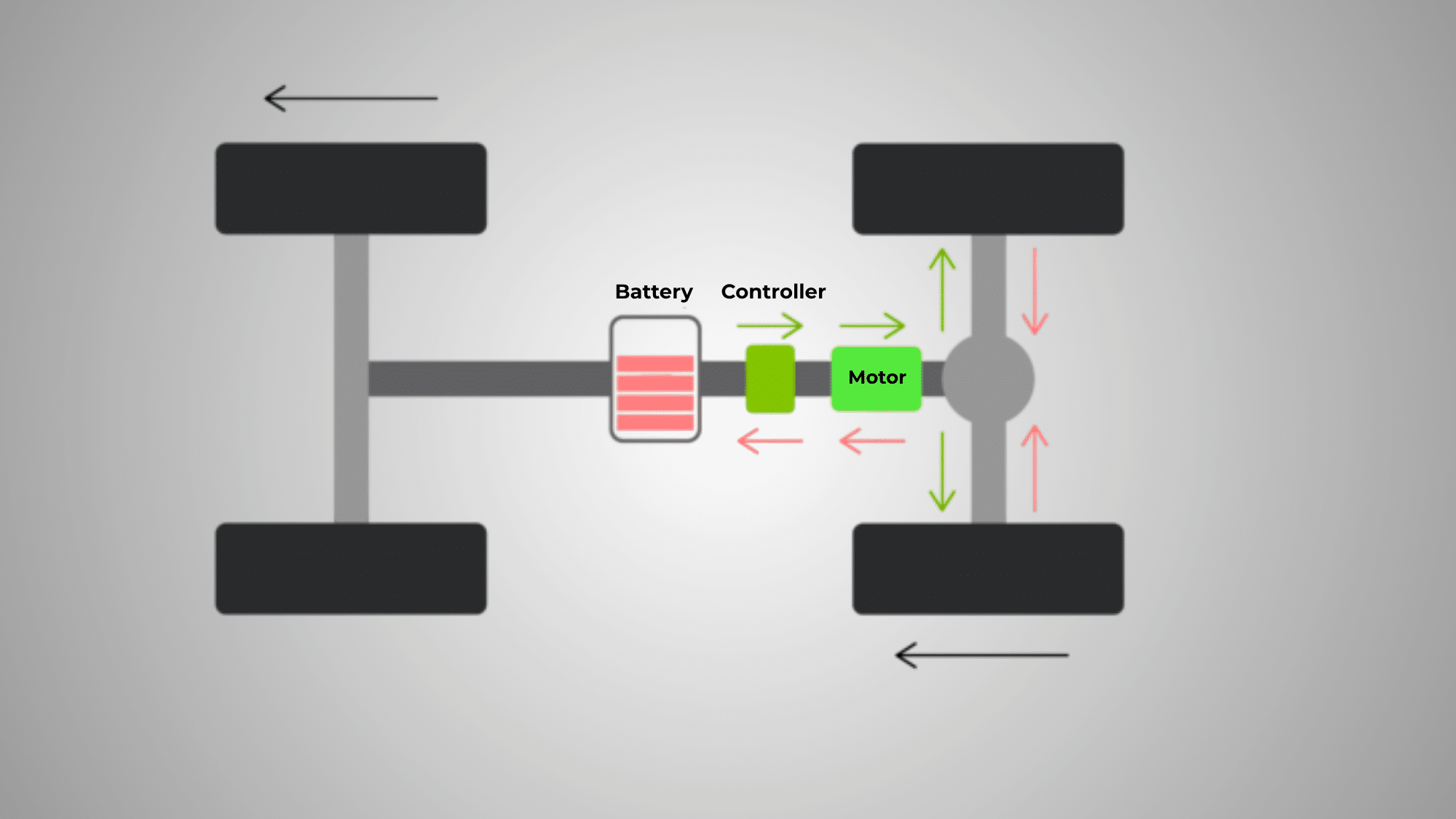

Regenerative brakes use the vehicle’s electric motor in reverse mode to slow the car while generating electricity. The system’s design centers around the electric motor’s dual capability to both propel and decelerate the vehicle efficiently.

When you release the accelerator or press the brake pedal, the motor controller switches the motor’s function from consumption to generation mode.

The motor’s rotor continues spinning from the vehicle’s momentum, but now acts as a generator producing electrical current.

This generated current flows through power electronics that convert it to the correct voltage for battery storage. An inverter changes the alternating current from the motor into direct current suitable for the battery pack.

How Does Regenerative Braking Work in an EV

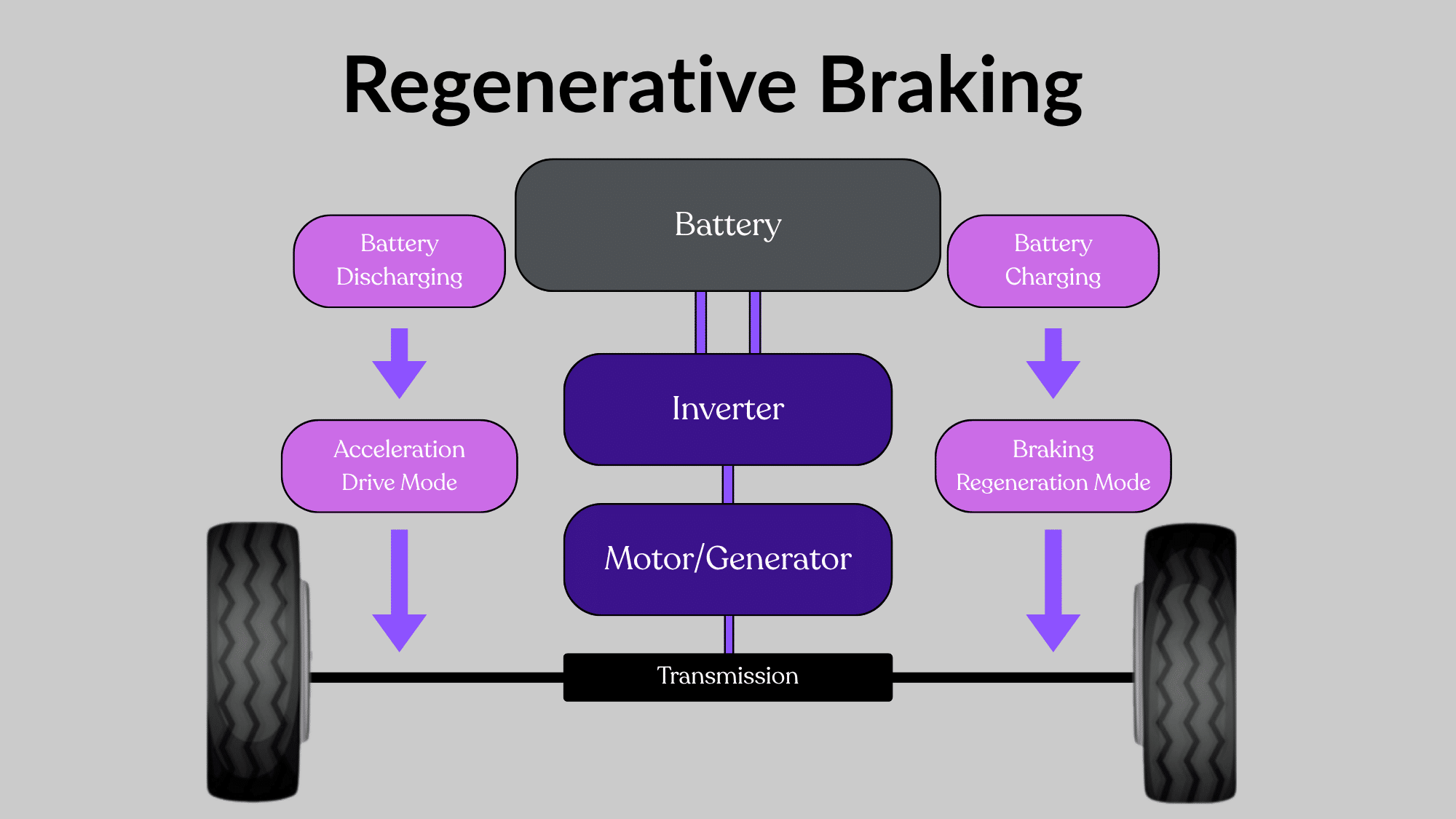

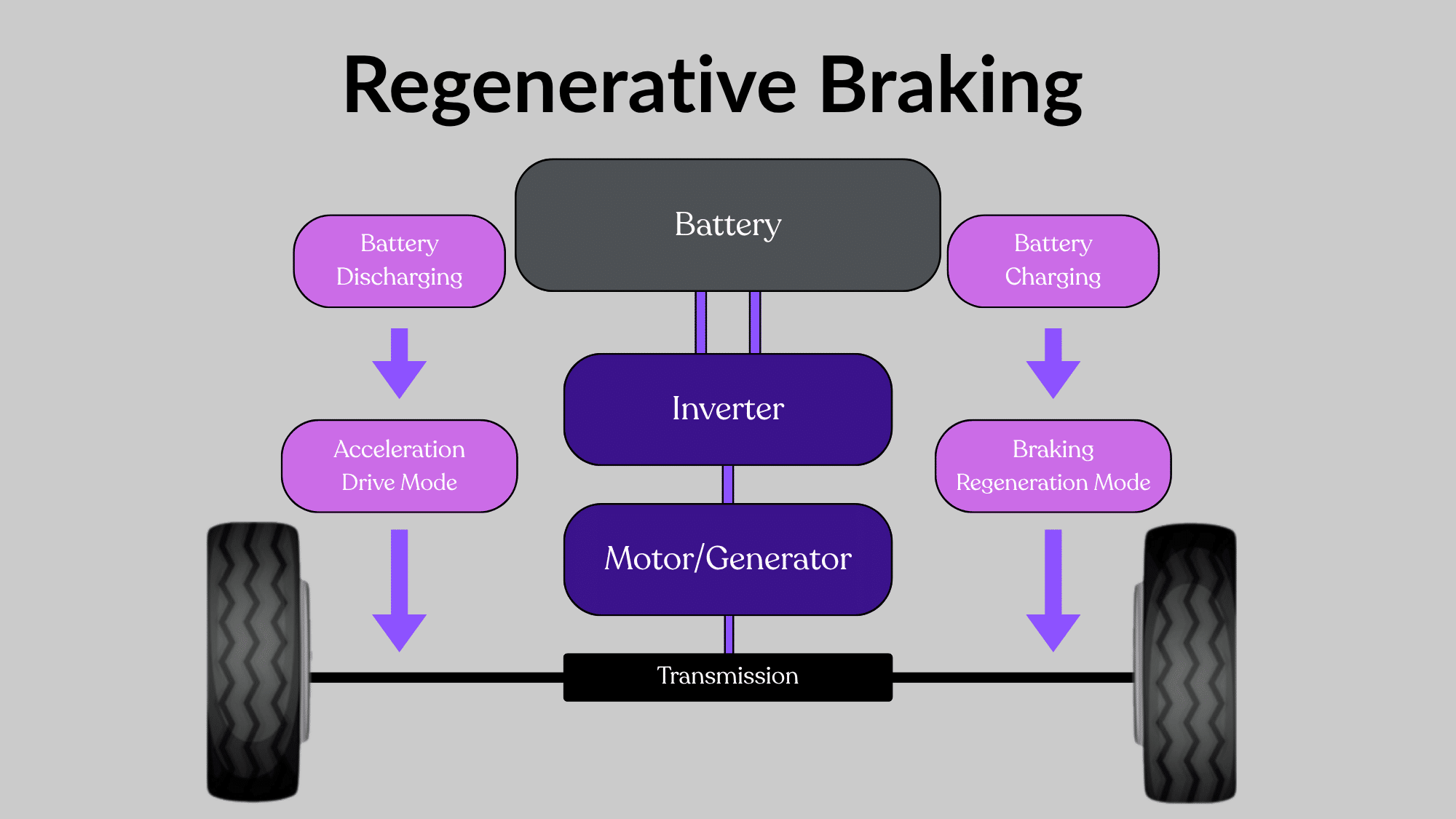

Understanding how does regenerative braking work involves five key stages that change motion energy into stored electricity for an extended range.

1. Motor Switches to Generator Mode

When you lift your foot off the accelerator pedal, the vehicle’s control system signals the motor to change roles. The electric motor that normally drives the wheels forward now becomes an electrical generator through electromagnetic principles.

The motor’s magnetic fields interact differently, creating resistance that opposes the wheel’s rotation and slows the vehicle.

This resistance generates an electrical current as the spinning rotor moves through the motor’s magnetic field continuously.

2. Kinetic Energy Converts to Electrical Energy

The vehicle’s forward motion contains kinetic energy that would normally dissipate as waste heat through friction brakes. As the motor functions as a generator, it captures this kinetic energy and changes it into usable electricity.

The spinning wheels turn the motor’s rotor, which moves conductors through magnetic fields to produce electrical current.

The amount of energy captured depends on vehicle speed, deceleration rate, and how much you’re slowing down.

3. Generated Electricity Flows to Battery

The electrical current produced by the generator motor needs proper conditioning before entering the battery pack safely. Power electronics regulate voltage and current levels to match the battery’s charging requirements and prevent damage.

Regenerative braking works by including the best electronics that manage this energy flow in milliseconds during operation.

The battery management system monitors temperature, charge state, and cell balance while accepting regenerated energy efficiently.

4. Vehicle Slows Down Smoothly

The resistance created by the generator motor provides smooth, progressive deceleration that feels natural to drivers. Unlike sudden friction brake application, regenerative braking offers gentle, predictable slowing that improves driving comfort significantly.

Drivers can modulate deceleration intensity by controlling how quickly they release the accelerator pedal pressure.

The system provides enough stopping power for most normal driving situations without engaging friction brakes at all.

5. Energy Gets Stored for Future Use

The captured electrical energy enters the battery pack, where it’s stored as chemical energy for later use. This recovered energy directly extends your driving range by reducing how much power the battery must provide.

The system can recover 10-30% of the energy used during typical driving, depending on conditions and habits.

How Often Should We Maintain a Regenerative Braking System?

Regular maintenance ensures regenerative braking works efficiently and safely, though it requires less attention than traditional friction brake systems.

- Battery health: Monitor battery condition annually, since regenerative efficiency depends on proper battery charging capacity and performance.

- Software updates: Install manufacturer software updates promptly to optimize regenerative braking algorithms and system performance improvements.

- Brake fluid: Check traditional brake fluid every two years, even though friction brakes receive less use overall.

- Friction brakes: Inspect brake pads and rotors annually, since reduced use can cause corrosion or uneven wear.

- Motor inspection: Have the electric motor examined during regular service intervals to ensure proper generator function capability.

- Sensor calibration: Verify brake pedal and wheel speed sensors work correctly during routine maintenance appointments regularly.

Pros and Cons of a Regenerative Braking System

Every technology has advantages and drawbacks, so understanding regenerative braking’s benefits and limitations helps drivers make informed vehicle decisions.

| Pros | Cons |

|---|---|

| Extends driving range by recovering wasted energy. | Higher initial vehicle cost from complex electronics. |

| Reduces brake wear and maintenance costs significantly. | Cannot capture energy when the battery is fully charged. |

| Provides smooth, comfortable deceleration for drivers. | Learning curve for traditional brake users. |

| Decreases brake dust and particulate pollution. | Less effective at very low speeds. |

| Improves overall efficiency by 30% approximately. | Cold weather reduces battery charging efficiency. |

| Reduces heat generation, preventing brake fade. | Requires maintenance for both braking systems. |

How Much Energy Can Regenerative Braking Capture?

The exact amount varies based on driving style, terrain, traffic patterns, and vehicle design characteristics throughout trips.

City driving with frequent stops captures significantly more energy than highway cruising at constant speeds without braking.

Aggressive driving with hard acceleration followed by hard braking recovers more energy but uses more overall power.

Smooth, anticipatory driving maximizes net efficiency by minimizing energy waste in both directions during operation. Battery charge level affects recovery since a full battery cannot accept additional energy from regeneration safely.

The Future of Regenerative Braking Technology

Regenerative braking technology continues evolving with improvements in efficiency, energy capture rates, and system integration across vehicle types.

Engineers are developing better algorithms that maximize energy recovery while maintaining a smooth, comfortable braking feel for drivers. Future systems may capture energy from suspension movement and aerodynamic drag beyond just wheel deceleration forces.

Solid-state batteries will accept regenerated charge faster and more efficiently than current lithium-ion technology allows today.

Integration with autonomous driving systems will optimize braking patterns to maximize energy recovery during self-driven journeys automatically.

Conclusion

Understanding the regenerative braking system reveals the clever engineering behind electric vehicle efficiency and range capabilities.

This system captures kinetic energy during deceleration and converts it back into stored electrical power for reuse. The motor switches roles from propulsion to generation, creating resistance that slows the vehicle while producing electricity.

While the system requires some maintenance attention, it significantly reduces wear on traditional friction brake components.

The technology represents a fundamental advantage that electric vehicles hold over traditional gas-powered cars.

Experience regenerative braking firsthand by test-driving an electric vehicle today.